Founded in 2010 and headquartered in Wuhu, Wuhu Anrui Optoelectronics Co., Ltd. (Anhui) has established four major production bases in Wuhu, Anhui; Hechuan, Chongqing; Taizhou, Zhejiang; and Birmingham, UK. As an enterprise integrating research, development, manufacturing, and sales, Anrui Optoelectronics focuses on technological innovation and information technology construction. After years of development, it has become a leading enterprise in the domestic automotive lighting manufacturing field and one of the fastest-growing companies in the history of the automotive lighting industry.

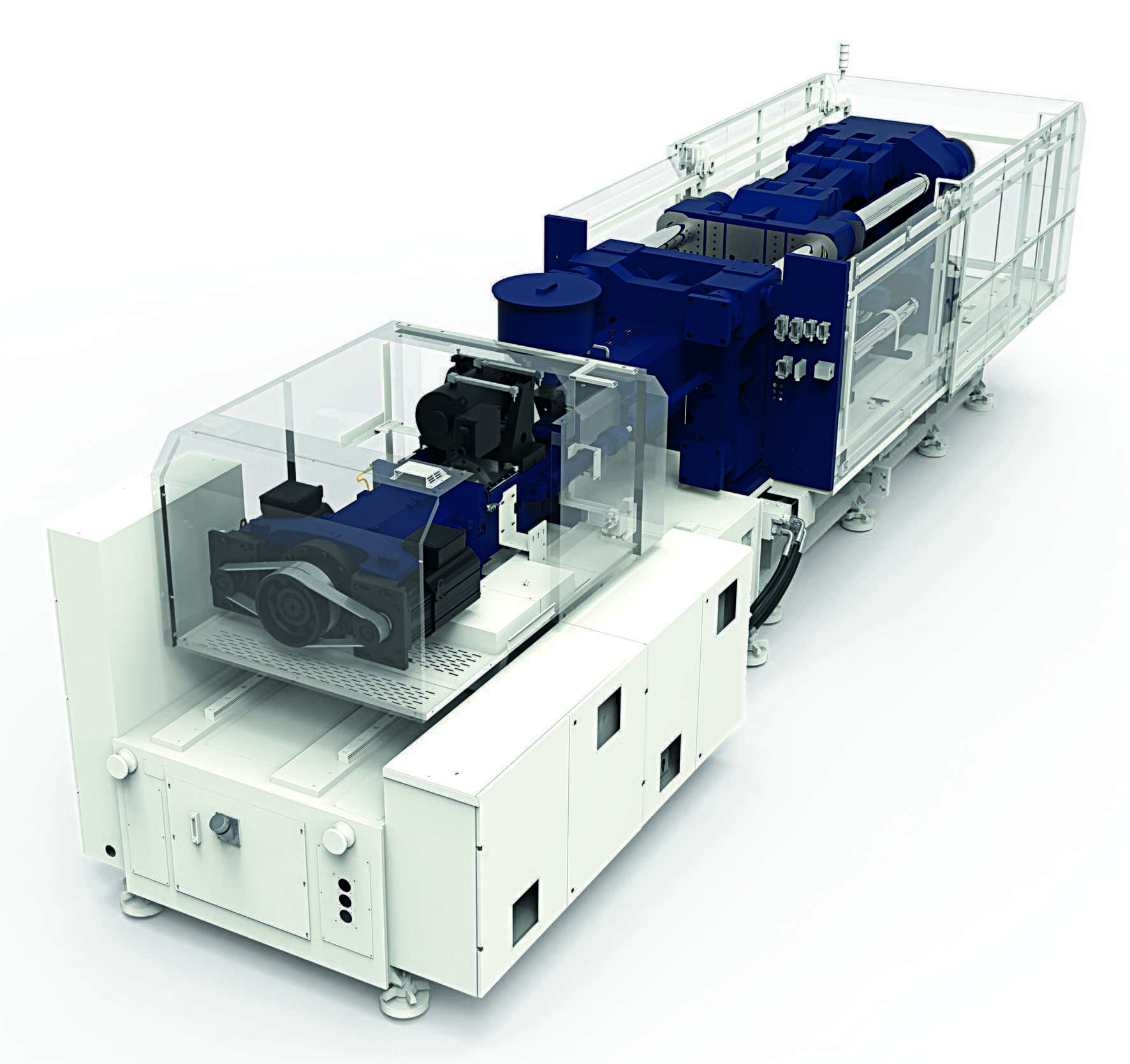

As early as 2018, Haitian and Anrui Optoelectronics began a close cooperation journey. We have jointly witnessed the birth of many “firsts” in China, witnessing Haitian’s technological progress and development in the field of large multi-component injection molding machines. Among them, the successful launch of the first 2100T vertical rotary two-color machine in China was a remarkable achievement of their cooperation.

This time, we have once again joined hands to achieve the successful mass production of the largest domestic vertical rotary 3300T multi-component machine. This achievement not only deepened the cooperative relationship between the two sides but also marked a significant milestone in their growth history.

Current Production of Changan Qiyuan E07 Front Full-width Light Bar at Chongqing Hechuan Factory

Current Production of Changan Qiyuan E07 Front Full-width Light Bar at Chongqing Hechuan Factory

Product dimensions: 1931*195*515mm

The 3300T vertical rotary two-color machine mainly produces large full-width light bars, with a maximum production capacity of 2.2 meters long, fully meeting the market demand for large-size, high-quality automotive lights.

Changan Qiyuan E07 Front Full-width light bar

As the largest tonnage multi-component equipment of the same series in China, the 3300T vertical rotary two-color machine has been developed based on Haitian’s mature and excellent two-platen technology platform, with a maximum mold rotating diameter up to 3100mm. It adopts dual servo motor control turntable technology, with a turntable bearing capacity of 28 tons. In addition, the equipment also has strong water and oil delivery capabilities to meet more complex and faster injection molding needs. The control accuracy of the turntable is as high as 0.005°, and the repeatability accuracy is up to ±0.5mm.

The successful birth and mass production of the 3300T vertical rotary two-color machine not only satisfied the need of domestic market but also provides customers with more possibilities for a high-performance, cost-effective alternative.

Building on this achievement, the collaboration between Haitian and Anrui?Optoelectronics once again highlights the innovative strength of Chinese manufacturing, fueled by new standards of quality and productivity. Looking ahead, Haitian and Anrui?Optoelectronics will continue to work together to drive development through innovation, promote technological advancement, and foster industrial upgrades.?

The post Haitian and Anrui Optoelectronics Deepen Cooperation appeared first on Haitian Group.

]]>On September 16, 2021, the Haitian Experience Center officially opened in Ningbo, China. The The venue creates an interactive experience that spans the history of Haitian, the present and the future.

On around 500 square meters at the Haitian Group headquarters in Ningbo, China, customers, partners and other visitors are now able to experience the Haitian brand up close. The showroom covers different topics such as Haitian’s origins, the branding of the individual divisions, their business areas as well as general brand values and company insights, future developmentsand many more. The individual topics are brought to life by a combination of state of the art technology such as interactive videos, virtual and physical objects, pictures and texts. The guided tour takes about 20-30 minutes and will be offered in several languages in the future.

With the Experience Center, Haitian not only provides an insight into the current operations of the individual divisions, but above all allows its visitors an outlook on its future developments especially in the digital sector. The showroom thus symbolizes the transformation of the company from a classic machine manufacturer to an innovative digital company, which has already begun.

Haitian welcomes all of its visitors to take a tour of the showroom.

The post Haitian Experience Center officially opened appeared first on Haitian Group.

]]>Haitian Vietnam Ltd. officially unveiled its new showroom in Ho Chi Minh City at a ceremony on 2021.1.5 The new building contains approximately 1000 sqm of multifunctional space modules for product display and meeting areas, after-sales training, spare parts storage and offices.

Zhong Saier, deputy general manager of Haitian Vietnam Ltd, Ho Chi Minh regional manager Yang Yingjun and business partners of the Vietnamese plastics industry at the official opening ceremony.

The centerpiece of the new showroom will be Haitian International’s state-of-the-art Generation 3 technology injection molding machines. Current exhibits include the world’s best-selling servo-hydraulic Haitian Mars III Series, the electric Zhafir Zeres III Series, and the two-platen servo-hydraulic Haitian Jupiter III Series.

Haitian Vietnam’s new showroom in Tan Du Industrial Zone, Duc Hoa District, Long Binh Province.

The Ho Chi Minh Showroom will not only serve as a showcase to present new technologies and solutions, but also as a central platform to strengthen the customer orientation of services in Vietnam, from state-of-the-art consulting and technical support to comprehensive services and mutually beneficial cooperation.

The Vietnamese economy has steadily improved its productivity in recent years and developed new strength together with foreign investors. Economic experts see great potential in the plastics industry in particular. Haitian International promotes this development in order to continue to open up the Vietnamese market and support plastics processing companies with efficient technologies and customized services.

The post Haitian opens showroom in Ho Chi Minh City appeared first on Haitian Group.

]]>

Stable performance in the global economic downturn +++ nearly 19,000 machines delivered worldwide in the first half of 2020 +++ 5,015.7 million RMB sales +++ Digital transformation of the company continues +++ Expansion of global presence

August 18, 2020, Hong Kong. Haitian International Holdings Ltd (“Haitian International”, together with subsidiaries and affiliates referred to as the “Haitian Group”; share code: 1882), one of the world’s largest manufacturers of plastic injection molding machines, announces its half-year results for 2020 (01.01.2020 to 30.06.2020).

Global economy and business performance

The outbreak of the Covid19 pandemic in early 2020 has led to business closures and suspensions in many countries around the world and dealt a severe blow to the global economy. The US-led global trade dispute and the trend toward deglobalization have further intensified. The global economy came to a standstill and fell into recession. In the middle of the global economic downturn, the Haitian Group sold nearly 19,000 machines worldwide in the first half of 2020. The revenues of Haitian International during this period amounted to 5,015.7 million RMB, which is an increase of 0.1%.

Domestic sales in the first half of the year reached RMB 3,320.6 million (RMB 3,320.0 million in the first half of 2019), unchanged compared to the same period last year. Nevertheless, sales have declined in most regional markets due to the pandemic. As part of the Haitian Group’s overseas network expansion, the local management teams performed well, with sales in Turkey, Vietnam and the Philippines showing a significant increase. Our export sales increased by 0.1% to 1,548.4 million RMB.

Outstanding Performance of Haitian Mars Sales

Due to increasing demand for medical, packaging and consumer goods industries under the global spread of Covid19 pandemic, Haitian’s bestseller Mars Series achieved a new record in terms of sales volume, with over 16,000 units Mars machines sold in the first half of 2020, representing an increase of 17.6% as compared to the same period 2019. The sales value of Mars Series totaled RMB 3,656 million RMB, representing an increase of 15.3%. The accumulative sale of Mars Series has exceeded 250, 000 units.

In the first half of 2020, Haitian also started to introduce the 3rd Generation machines in step by step in certain region and the positive feedback from the customers’ side also paved ways for the smooth transition from second to third Generation machines.

Outlook and future strategy

Mr. Zhang Bin, Executive Director of Haitian International, about his views on the global economy: “The Covid19 virus has brought economic activity around the world to a standstill and will continue to affect the global economy after the pandemic. Trade conflicts, deglobalization and geopolitical crises between countries will pose further risks. The major economic organizations have already significantly lowered their expectations regarding the global economy. China’s government has taken a number of economic policy measures that will enable the domestic economy to grow steadily. We remain optimistic about the outlook for 2020”.

With regard to the development of the Haitian Group, Mr. Zhang added: “We will continue the digital transformation of the company at full speed. From the implementation of digital tools for intelligent manufacturing to digitally supported sales & service. Intelligent information systems for management and administration are also included. Our instances in China will be better networked than ever, with all locations around the globe. Another important strategy parallel to digitalization is the continuous expansion of our global presence. Under our proven strategy of “Technology to the Point”, we will continue to meet changing and diversified market demand. We will continue to develop and grow together with our customers, employees and business partners”.

The post Half-yearly balance 2020: Positive developments – against the global trend appeared first on Haitian Group.

]]>

On July 2nd, the ceremony of “2020 Ringier Technology Innovation Award for Plastics Industry” was held in Shanghai. Hundreds of representatives of award-winning enterprises, representatives from the association, journalists from the industry media and other industry professionals gathered together, to share and exchange the in-depth change brought about by the innovative products and technology from the plastics industry.

The VEIII series fully-electric injection molding machine of Ningbo Zhafir Plastic Machinery Manufacturing Co., LTD stood out among a vast number of competing products and won the “2020 Ringier Technology Innovation Award”. Mr. Jin Biao, deputy general manager of Ningbo Zhafir, expressed thanks to Ringier industrial media: ” We are very honored to win this ‘2020 Ringier Technology Innovation Award’, which will further inspire our team to continually explore the possibility of electric injection molding technology and provide our customers with solutions with technology to the point to address their actual needs and achieve value co-creation. “

Zhafir VEIII series fully electric injection molding machine has a lot of improvements in terms of precision, intelligence, cleanliness etc. It can be widely used in the production of medical, electronic and precision parts. Since its premiere at the K2019 in Germany last year, it has received great attention in the industry. The latest technology generation of the premium brand Zhafir offers beneficial updates as well as new developments in hardware and software. Optimized drives and an open integration strategy for robotics and automation increase the scope for investment and flexibility in production. Ongoing improvements and the consistent development of standard components such as motors result in higher performance but also higher overall resource savings.

Finally, Mr. Jin added, “as a young and energetic team, Zhafir is convinced that innovation drives development, and we will continue to be committed to bring the benefits of electric injection molding technology to more and more customers.”

The post Zhafir VEIII series won the 2020 Ringier Technology Innovation Award appeared first on Haitian Group.

]]>

On June 18, the “Haitian University” which co-founded by Haitian Group and Ningbo Polytechnic was officially established, and a signing and equipment donation ceremony were held in Ningbo Polytechnic. Officers Zhang Haihang, Fu Zhongxing, Zhong Ying, Wang Saiping, from Beilun District Government. Yu Wenxian, Director of Human Resource Department of Haitian Group and Mr. Zhang Huibo, Deputy Secretary of the Party Committee and Dean of the Ningbo Polytechnic, and other officers from government, school and enterprise, student representatives attended the ceremony.

At the meeting, Mr. Zhang Huibo and Mr. Yu Wenxian signed a cooperation agreement on behalf of the school and Haitian for joint foundation of “Haitian University”. Afterwards, Mr. Zhang and Mr.Yu delivered speeches respectively. Mr.Yu said that the initiative of foundation of “Haitian University” is to integrate and connect the global innovation resources, to proactively serve Ningbo and the global manufacturing industry, to train skilled talents, and contribute to the manufacturing power of our city and country. Mr. Zhang Huibo emphasized that the establishment of “Haitian University” marks another milestone in cooperation between Haitian Group and Ningbo Polytechnic, and it will definitely bring out the synergy from the cooperation among the industry, the R&D and education fields, to further enhance the development of the vocational education in the new era.

Ningbo Polytechnic and Haitian signed a donation agreement, in which Haitian Group donated RMB 2.2 million machinery to Ningbo Polytechnic for use of training, scientific research and social services. At the same time, both parties also announced the foundation of “Ding Xiaojun Master Studio” to further strengthen the training of skilled talents.

Since 2002, Haitian Group has been in close cooperation with Ningbo Polytechnic and has jointly trained and recruited a great number of outstanding technical talents, and create a number of projects for school-enterprise cooperation. The establishment of “Haitian University” is not only a test field for the integration and comprehensive reform of higher education, vocational education and human resources development of enterprises, but also a milestone for the integration of industry and education between schools and enterprises, and the cultivation of technical talents that are closely integrated with enterprises. Both schools and enterprises will make full use of the advantages of resources, teaching, and talents of leading enterprises and vocational colleges in the industry, focus on the intelligent manufacturing industry, and conduct comprehensive cooperation in the fields of talent training, scientific research innovation, and entrepreneurship incubation to promote professional talent training and industry transformation and upgrading. To build a community of shared destiny and achieve mutual benefit and win-win results.

The post “Haitian University” was officially established appeared first on Haitian Group.

]]>

In early April 2020, the Governor of Zhejiang, Mr. Yuan Jiajun, accompanied by a high-ranking delegation, visited several Haitian International manufacturing plants to get an up-to-date picture of the resumption of production. Mr. Zhang Jianming, CEO of Haitian Group, Mr. Zhang Jianfeng, CEO of Haitian Plastics Machinery Group, and Mr. Zhang Jingzhang, Chairman of the relevant department group, did not miss the opportunity to welcome Mr. Yuan and his delegation.

After a short introduction to the companies and the industry portfolio of Haitian Group, the guests inspected the production workshop and production lines of Haitian Plastics Machinery and the Haitian Precision plant. They attentively followed the presentations on the implementation of the smart “8 + 16” production mode and on the high-end CNC machines developed by Haitian Precision, which will now compete with international competitors in the local market.

The Governor encouraged Haitian International in its strategy of “focus and expansion through diversification” and in its mission to equip China and the world. He emphasized that Haitian International should continue to pursue the approach of independent innovation and development by promoting intelligent manufacturing, and that the Group should continue to contribute to the development and transformation of key industries such as aerospace and the use of new energy for vehicles.

He also urged Haitian International to take advantage of the development opportunities in the “post-epidemic period” and, in view of the world’s most advanced technologies, to further enhance its own competitiveness.

Mr. Zheng Shanjie, Deputy Secretary of Zhejiang Provincial Party Committee and Secretary of Ningbo Municipal Party Committee, Mr. Hu Kui, Deputy Director of Zhejiang Development and Reform Commission, Mr. Qiu Dongyao, Deputy Secretary and Mayor of Ningbo Municipal Party Committee of Zhejiang Province, and Mr. Liang Qun, Secretary of Beilun District Party Committee, were also present in this visit.

The post Governor visits Haitian International appeared first on Haitian Group.

]]>

WITH STRICT CONTROL MEASURES AND BROAD SUPPORT FOR EPIDEMIC PREVENTION

April 6, 2020, Ningbo, China. In view of the improved situation in the prevention and control of the Covid-19 epidemic in China’s interior, it is time to accelerate the restoration of order in the everyday life of the population and to resume work processes for the production of essential goods. As a leader in plastic injection molding machinery, Haitian International assumes social responsibility for its employees, society and its suppliers, while strengthening the prevention and control of the epidemic.

Even after resuming production, Haitian International strictly adheres to the principle of “complete prevention and control”. For example, we dynamically check the health status of the employees, strictly control the personnel when entering or leaving the factory, and eliminate any hygiene weaknesses in public areas. Our canteens remain closed to avoid large crowds of people, but instead we rely on online offices to reduce the risks as much as possible.

Parallel to the implementation of all preventive measures, we have taken the reins of action. It is necessary to speed up the planning of work resumption and production in the supporting industries, to keep production stable overall and to optimize the annual production plan. Both the delivery of ordered products and the production of urgently needed materials for epidemic containment must be fully guaranteed. One of the priority objectives is to minimize the impact of the epidemic and to create a basis to take advantage of market opportunities once the epidemic has subsided.

More than 4,000 units delivered in one month

Since the resumption of work on February 10, Haitian International has given priority to supporting the production of the materials needed in the front line of epidemic prevention work. In the course of this, we organize preferentially the production and shipment of important materials and products, such as respirators, temperature thermometers, protective goggles, disinfectants, and fast food boxes. The production line of the company is working at full capacity. All employees work overtime to meet the required workload.

In March, the subsidiary Haitian Plastics Machinery delivered more than 4,000 machines and received orders of nearly 5,000 machines. In times like these, this is a result that gives courage.

Actively leading the way as a production driver

As a leading company in the field of injection molding machines, Haitian International has been confronted with various challenges within the industrial process chain since resuming operations, for example in interregional logistics or due to the insufficient supply of supporting products.

In order to advance and guarantee production, we support the companies of the upstream and downstream market sectors in resuming their work and production. For example, we have established an integrated mode for epidemic prevention and industrial cooperation. At the same time, Haitian International supports the city and district governments in the context of priority assessments on the part of industrial suppliers and process partners.

Since the processing industry is at high risk of infection due to the number of non-local employees, Haitian International has taken the initiative and is financing the nucleic acid test for personnel returning to Ningbo. The smooth implementation of the epidemic prevention work is thus also guaranteed in the supporting companies.

In order to alleviate the current high financial pressure of the supporting companies, Haitian International also made advance payments for the purchase of raw materials in order to support their way back to normal production strength.

Haitian International will continue to keep the safety and well-being of customers, employees and suppliers as our top priority as we follow the path to normal operations.

The post RESUMPTION OF PRODUCTION appeared first on Haitian Group.

]]>

HIGH-PERFORMANCE DRIVE SYSTEMS WITH INTELLIGENT MOTION CONTROL

+++ Cost-efficient, flexible, reliable: Haitian machines are more powerful and economical than ever before. With clamping forces from 600 to 66,000 kN and pinpoint solutions for all standard applications. Precise and reliable in the movements of all axes, thanks to Motion Plus and a new generation of servo-hydraulic drives – tailor-made and yet cost-efficient?+++

The latest technology generation of the Haitian brand offers beneficial improvements as well as significant new developments in hardware and software. Optimized drives and an open communication strategy for automation and any interfaces increase the scope of action for the processor and flexibility in production because Haitian leaves the customer absolutely free choice of integration partners. Continuous improvements and the consistent further development of standard components such as the successful “Mars Technology” result in higher performance but also higher overall resource savings.

“The new generation of hydraulic servo drives in combination with a new inverter generation promises more power and ensures more precise movements of all axes,” says Mr. Fu Nanhong, Chief Engineer of Haitian International in Ningbo, China. Thanks to intelligent algorithms, the injection process control has been optimized by replacing proportional valves with standard valves – closed-loop, without sacrificing speed and pressure.

OPEN INTEGRATION WITH CONNECTIVITY PLUS AND MOTION PLUS

The 3rd technology generation is no longer just a hardware update. Rather, it is a system or platform with intelligent and extremely fast adaptive software. Mechanics, Motion Plus and connectivity form a strong symbiosis and are in healthy balance with each other.

Haitian’s in-house developed software solutions offer the processor a very high degree of flexibility in the process optimization of all axes. Based on the OPC-Unified Architecture (OPC-UA) standards, the software enables extremely open integration or connectivity with all common interfaces and seamless connection of industrial automation or any MES system. Mr Fu Nanhong: “We provide the customer an intelligent machine system that is open to all possibilities while leaving him free choice of integration partners”. In this way, the highly standardized Haitian machines can be easily integrated into any automated process – maximum flexibility with the best possible productivity.

AT A GLANCE: CONNECTIVITY PLUS

- Simple connection via integrated OPC-UA interface for secure and reliable data exchange

- Communication to all internationally common interfaces such as Euromap 77, 82 and 83

- Business to Machine – integration into vertical MES systems

- Enhanced data compatibility with the ability to transform heterogeneous data from edge computers

Motion Plus is the bundling of already established and new developments around intelligent motion control. For the Haitian series it was a big step towards the digital future through digital intelligence. “This may not sound spectacular across all competitors, but given the enormous power of manufacturing and service capacity, this technological leap is taking on a new meaning,” says Mr. Fu.

AT A GLANCE: MOTION PLUS

- The bundling of already established and new developments around intelligent motion control

- Tailor-made hydraulic unit for fast reaction and more precise tuning

- High-speed real-time fieldbus with large bandwidth

- High precision close-loop control of the injection process

OUR HAITIAN EXHIBITS AT K2019

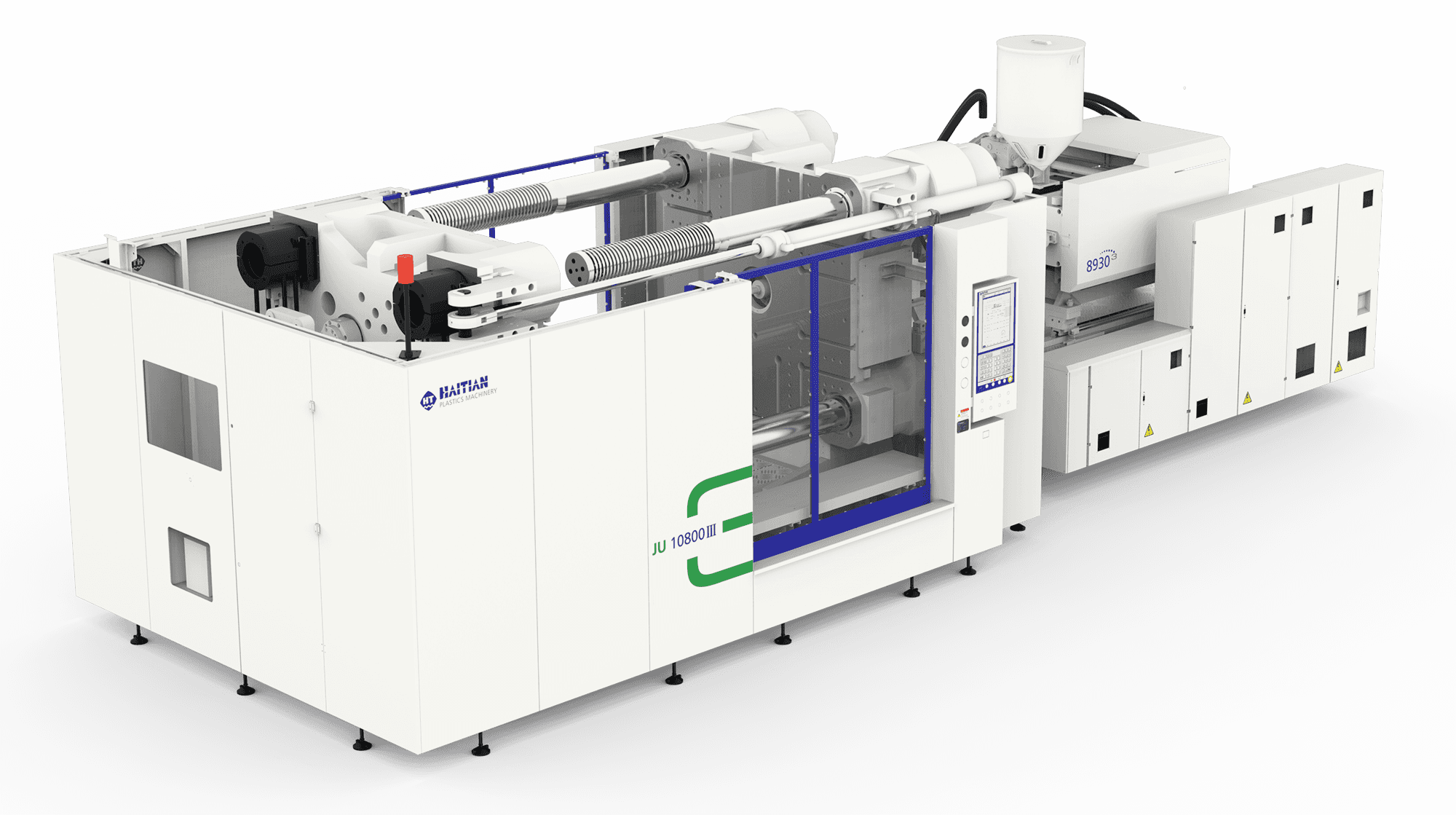

Compact solution for large automotive parts: Haitian Jupiter III Series

Compact two-platen solution with plenty of space for large molds and the latest control technology. Design updates lead to more stable platen movements and shorter dry cycle times. A JU5500III/2230 produces a LED light strip for VW out of PC, integrated into a production cell with assembly, sorting and removal using a 6-axis robot from ABB.

Economical solution for consumer goods: Haitian Mars III Plus Series

To date, the standard version of our Mars Series is the world’s best-selling injection molding machine with over 230,000 units placed in the field. The servo-hydraulic bestseller presents itself in the 3rd generation with new motors, optimized injection unit and a new sheet metal design. A MA1700III/plus produces bottle openers from 100% PP recyclate with insert technology, integrated in a production cell including a robot from Haitian Drive Systems.

OUTLOOK

The innovative servo-hydraulic drive technology of the Haitian Mars Series has been inspiring since 10 years through its outstanding economic efficiency and reliability. Haitian engineers are constantly working on optimizing the hardware components. The focus here is on dynamics, precise movements and process accuracy, as well as standardization with maximum flexibility.

“Our goal is to maintain a healthy balance between hardware and software,” says Mr. Fu Nanhong. “In our opinion, intelligent motion control can only develop into a real customer advantage and offer new possibilities with thoughtful and above all cost-efficient hardware.

The post THE NEW TECHNOLOGY GENERATION 3 OF HAITIAN: appeared first on Haitian Group.

]]>

?ELECTRIC OPPORTUNITIES IN A NEW DIMENSION

+++ With the 3rd technology generation, the strongest Zhafir family of all time enters the market with clamping forces from 400 to 33,000 kN and pinpoint solutions from all-electric to hybrid. Highly precise, energy-saving and attractively priced. From dynamic high-speed machines to the new, big – and yet affordable – electric injection unit +++

The latest technology generation of the premium brand Zhafir offers beneficial updates as well as new developments in hardware and software. Optimized drives and an open integration strategy for robotics and automation increase the scope for investments and in production. Ongoing improvements and the consistent development of standard components such as motors result in higher performance but also higher overall resource savings.

The all-electric Venus Series in the 3rd generation of Zhafir again provides the basic technology for all other electric Zhafir Series machines. The highly flexible Zeres Series – which already addresses the widest range of applications due to its integrated hydraulics for core pull applications – has also been extended by specifically designed solutions for fast processes or multi-component tasks.

One of Zhafir’s new developments is the intelligent combination of hardware and software. A very innovative example is provided by the electric injection unit with its 4-spindle principle. “Here you can see the perfect symbiosis of software and hardware,” says Mr. Zhang Bin, CEO of Zhafir Plastics Machinery. “The challenge was the exact synchronization of all four spindles. This is only possible with extremely powerful, reliable but also flexible components that are controlled by an intelligent control center.”

OPEN INTEGRATION WITH CONNECTIVITY PLUS AND MOTION PLUS

The 3rd technology generation is no longer just a hardware update. Rather, it is a system platform with intelligent and extremely fast adaptive software.

Our in-house developed software solutions offer the processor very high flexibility in the process optimization of all axes. Based on the OPC-Unified Architecture (OPC-UA) standards (for platform, system architecture, communication and data transfer), they enable extremely open integration and connectivity with all common interfaces and seamless connection of industrial automation or any MES system.

CONNECTIVITY PLUS

- Versatile communication interfaces and device integration functions

- Interoperability protocols and information models for coordinating the injection molding machine with peripheral equipment and automation cell

- Business to Machine – integration into vertical management systems

- OPC Unified Architecture – interoperability as standard for secure and reliable data exchange in the field of industrial automation

- Enhanced data compatibility with the ability to transform heterogeneous data from edge computers

Mr. Fu Nanhong, Chief Engineer of Haitian International, explains: “We provide the customer an intelligent machine system that is open to all possibilities while leaving him free choice of integration partners”. This allows the highly standardized Zhafir machines to be integrated into automated processes, cells and production lines as required – maximum flexibility with the best possible productivity.

MOTION PLUS

Motion Plus is the bundling of already established and new developments for intelligent motion control. “This may not sound spectacular at first, but given the enormous manufacturing power and service capacities, this technological advance is taking on new significance,” says Mr. Fu Nanhong. “Motion Plus combines hardware and software into a high-performance symbiosis.”

OUR EXHIBITS AT K2019

Even though the technological advance in the Zhafir Series is not not excessively big – the Zhafir Series has been continuously developed – the electric technology in Generation 3 presents itself even more customer-oriented thanks to an optimized toggle design and new injection unit – especially in the upper clamping force segment.

Prototype of the new electric Zhafir injection unit

A very innovative example is the new electric injection unit with 4-spindle principle. “Here you can see the perfect interaction of software and hardware,” says Mr. Fu Nanhong. “The challenge was to exactly synchronize the software and hardware for all four spindles. The multi-axis control technology is based on servo torque direct drives. This is only possible with extremely powerful, reliable, but also flexible components that are controlled by an intelligent control center.”

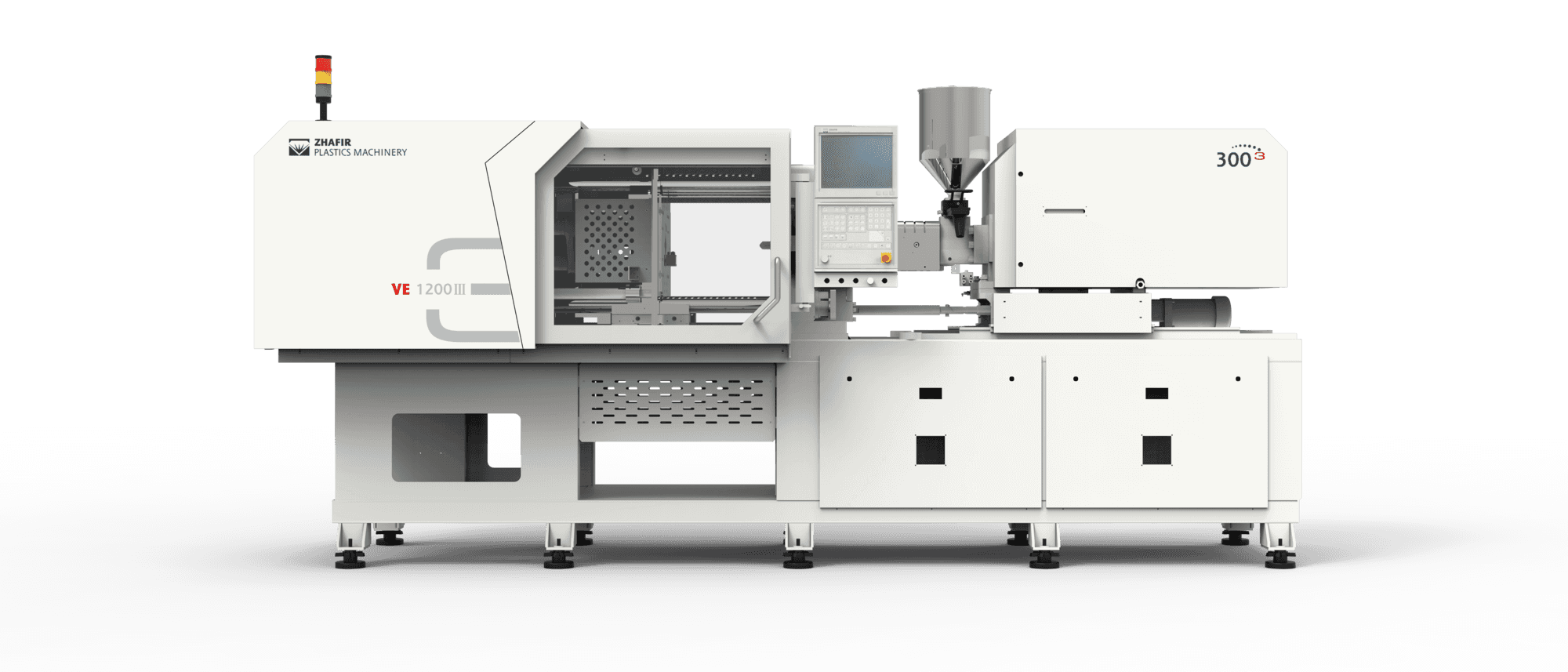

Clean, electrical solution for Medical: Zhafir Venus III Series

All-electric dynamic with highest precision and up to 70 % energy savings. A VE1200III-300 produces a medical part made of PP under a laminar flow box from Max Petek.

Dynamic solution for packaging: Zhafir Zeres F Series

Electric solution with integrated hydraulic drive. The 3rd generation ZE2300F-830 produces a 4-cavity lid with in-mold labeling (IML), both made of PP, in a Sepro Robotique production cell.

Outlook

“Efficient and smart manufacturing processes and high-volume production make customized components a cost-efficient standard,” says Mr. Fu Nanhong. “We could also call it tailor-made standardization. This opens up completely new perspectives for the entire company. “Customized drives, intelligent software and the unique manufacturing power in the Haitian Group allow us to think even larger in terms of electric drives and to further expand the still attractively priced range of electric concepts – Especially large clamping forces and, above all, large and affordable injection units.

The post THE NEW TECHNOLOGY GENERATION 3 OF ZHAFIR:? appeared first on Haitian Group.

]]>