From September 27 to 28, Haitian Thailand held a two-day open day in Bangkok, attracting many local clients and Chinese enterprises. This open day showcased Haitian International’s innovative technologies and significant achievements in its globalization strategy, fully demonstrating Haitian’s deep foundation in the Thai market.

At the start of the event, Mr. Shi Zheng, General Manager of Haitian Thailand, delivered a welcoming speech to the guests. He shared Haitian International’s globalization strategy and emphasized the importance of Thailand as a regional application center in enhancing local operations and customer service.

The event featured several molding solutions specifically developed for the Thai market, including Haitian injection molding machines from the MAV, MA/GⅡ, MA/F, MA/WM, JU/SE, HA/PET series, as well as Niigata injection molding machines. These machines cover a wide range of applications, from consumer products to automotive manufacturing. Haitian’s latest fifth-generation technology, praised for its intelligence, energy efficiency, and high performance, received widespread acclaim from the attendees. Other Haitian Machinery solutions, such as CNC machining centers from Haitian Precision and thixomolding machines from Haitian Die Casting, were also showcased during the open day.

Through live demonstrations, technical explanations, and interactive sessions, customers were able to gain a more direct understanding of the performance features of the products. This not only enhanced their recognition of Haitian but also strengthened customer loyalty.

As a global leader in machinery manufacturing, Haitian International has been deeply engaged in the Thai market for over 20 years. In 2016, it established a wholly owned subsidiary in Thailand, continuously driving the upgrade and development of the local manufacturing industry. With the continuous growth of the global economy and increasingly close trade relations, Southeast Asia, with its unique geographical advantages, abundant labor resources, and cost-effectiveness, is gradually becoming an important hub for global manufacturing. Thailand, as a key economy in Southeast Asia, offers an ideal environment for Haitian’s investment and factory establishment.

The successful hosting of this open day not only showcased Haitian International’s strong presence and brand influence in the Thai market but also deepened exchanges and cooperation between Haitian and local clients. Furthermore, it provided solid support for the development of Chinese enterprises in Thailand and the broader Southeast Asian region. In the future, Haitian will continue to deepen its globalization strategy by leveraging technological innovation and localized operations to provide better products and services to customers worldwide.

The post Haitian Thailand Open Day appeared first on Haitian Group.

]]>On September 26, the delivery ceremony of the JU24000M horizontal rotary multi-component injection molding machine was successfully held. The delivered machine, from Haitian’s JU series, boasts a clamping force of 2,400 tons, setting a new record for horizontal rotary multi-component injection molding machines in South China. This milestone not only highlights Haitian’s technical strength and innovative capabilities in the injection molding field, but also marks a significant achievement for the company.

The delivery ceremony was held at the Jiangnan Road Plant. Senior leaders from both companies attended the event, including Gao Jielin, Vice General Manager of Haitian Group’s Multi-Component Product Line, Chen Chufan, General Manager of Hengyiyuan Plastic Mold Co., Ltd., and Xu Renjie, Assistant to the General Manager of Haitian Group’s Multi-Component Product Line. Together, they witnessed this important moment.

At the ceremony, Gao and Chen completed the equipment acceptance and formal handover on behalf of their respective companies.

The Haitian JU24000M is the largest horizontal rotary multi-component injection molding machine in terms of clamping force ever delivered in the South China market. Its unique design and powerful features give it an irreplaceable advantage in the production of automotive headlight covers. In response to Hengyiyuan’s specific requirements as a mold manufacturer, the machine is equipped with double injection units on both sides of the movable and fixed platens, which can switch to the center as needed. Additionally, the configuration of different screw sizes greatly enhances the machine’s versatility and flexibility, better meeting the diverse production needs for headlight covers.

Furthermore, the injection unit incorporates the latest digital control and fully closed-loop control technologies, enabling high-precision control of the injection process. This ensures stable and high-precision production of headlight covers, providing strong assurance for product quality.

The successful delivery is the result of years of deep cooperation between Haitian Plastic Machinery and Hengyiyuan Plastics, as well as Haitian’s continuous pursuit of technological innovation and advancements in core technologies. Looking ahead, Haitian will continue to concentrate its resources on promoting technical innovation in specialized fields, accelerating the development of advanced equipment. Haitian remains committed to providing superior and efficient production solutions for customers across various industries, including the automotive sector, achieving new breakthroughs in professional fields.

The post A New Record in South China: Haitian JU24000M Successfully Delivered appeared first on Haitian Group.

]]>Recently, the two-platen Haitian Jupiter 88000, a superlative injection molding machine, was officially delivered to France. After the handover ceremony in October 2023 in Ningbo, China, the machine successfully arrived in France in August 2024 after months of careful planning and international logistics and was smoothly installed and commissioned at the BELLI factory.

Official Delivery of the Haitian JU8800T Ultra-Large Injection Molding Machine in France

The Haitian JU88000 is the result of the know-how and hard work of Haitian engineers at every stage of development, from design to production. With its impressive clamping force of 88,000 kN and an injection capacity of 134,000 cubic centimeters, it sets a new record in the injection molding machine industry and marks a significant breakthrough in injection technology in large-scale machine manufacturing.

The massive transportation operation, included 17 trucks delivering the machine and peripherals parts weighing a total of 800 tons. It is also the first time that such a large-scale machine has been shipped from China to a European industrialized country, significantly enhancing China’s competitiveness in high-end markets and marking a new milestone for Haitian manufacturing on a global scale.

The Transoceanic Journey of the Haitian JU8800T Ultra-Large Injection Molding Machine

The Haitian team faced the challenges of transporting equipment over long distances and with high weight through different countries and made tremendous efforts to ensure the safe and smooth arrival of this “giant”. The transportation required a tailor-made sea freight plan and careful planning and execution of every detail of the cross-border transport.

Assembly and installation on site

Upon arrival in France, Haitian’s technical team from Germany, Serbia, China and SAS Haitian France immediately began the intensive assembly and commissioning work. From disassembly to assembly and installation, every step was carried out with the utmost care and precision.

With 9 engineers working continuously for 5 weeks, the Haitian JU88000 was successfully installed and is now ready for operation at the BELLI plant of Nurieux (01 FRANCE) increasing his capacity to produce packaging, houseware and garden/house environment goods. Throughout the process, the Haitian team was in close contact and collaboration with the French customer to share this important moment of delivery.

Official Delivery

The successful installation and delivery of the Haitian JU88000 injection molding machine to France not only represents a major breakthrough for Haitian in the injection molding machine industry, but also provides valuable technical experience for the global plastics processing sector.

The post JU88000: Successful Delivery and Assembly in France appeared first on Haitian Group.

]]>On August 15th, Haitian Mexico held a grand Open Day in Guadalajara, Mexico. This event not only allowed local customers to learn about Haitian International’s latest technological innovations but also served as a comprehensive display of the company’s commitment to deeply rooting into the local market and strengthening localized delivery and service capabilities.

1. Localized Operations Stressed to?Build Global Competitiveness

The event kicked off with traditional Mexican music, creating a lively and culturally rich atmosphere. At the event, Mr. Xu Biyun, General Manager of Haitian Mexico, delivered a speech, detailing Haitian Machinery’s global strategy and emphasizing the crucial role of Haitian Mexico as a regional center in enhancing localized operations and customer service.

Mr. Xu emphasized that Haitian International is a global leader in injection molding machine manufacturing, constantly driving product innovation and iteration based on market demands. Leveraging Haitian group’s layout in multiple fields from CNC machines, to die casting, laser machinery, drive technology, and smart manufacturing, Haitian is able to provide one-stop solutions in the machinery and equipment sector.

In recent years, the company has continuously deepened its overseas development strategy, actively establishing regional management centers, manufacturing centers, as well as application and service experience centers in key global markets. This is to fully meet the region-specific needs of local markets, earning the trust of many overseas benchmark customers and go-global Chinese enterprises through a well-established localized supply chain and efficient, convenient local services and support.

Haitian Mexico is a crucial part of Haitian’s global strategy. Serving as a regional management and manufacturing center for the Americas, Haitian Mexico has gradually expanded its market influence and localized delivery capabilities since its operation in 2022. It not only serves the Mexican market but also gradually extends its coverage to the entire Americas. Through this hub, Haitian can respond more quickly to the needs of customers in the Americas, providing one-stop solutions, thereby further enhancing customer satisfaction.

2. A Technical Feast: from Solution Demonstrated to Client Interaction

During the Open Day, Haitian Mexico showcased several injection molding solutions designed for the Americas market, including the Haitian MA2000V/750, Haitian JU5500V/3450, Zhafir ZE1500V-300, and Zhafir VE1900Ⅲ-640h, covering various application fields such as automotive, home appliances, and consumer electronics. These solutions fully demonstrated Haitian’s continuous iteration and optimization in injection molding technology around areas of interest to customers, such as energy efficiency, intelligence, and sustainability, drawing the attention of many industry experts and customers. Additionally, products from other Haitian Group divisions, such as CNC machines, die-casting machines, and smart manufacturing one-stop solutions, were also showcased.

At the event, Haitian Mexico’s technical experts provided detailed demonstrations of the equipment’s innovative features and user-friendly operations, engaging in in-depth technical exchanges with customers. This allowed customers to gain a more comprehensive understanding of Haitian’s products and services, not only deepening their understanding of Haitian’s advanced injection molding technology but also fully appreciating Haitian’s strategic vision and professional capabilities in perfecting the industry chain.

3. Looking Ahead:?Strategic Vision and Forward-looking Planning

In the future, Haitian Mexico will continue to refine its strategic layout as a regional center, continuously deepening its delivery and service capabilities in the local market. It is committed to focusing on the personalized needs of local customers, providing more efficient and energy-saving solutions, and helping customers stand out in a highly competitive market. Together with customers and partners, Haitian Mexico aims to establish long-term, stable cooperative relationships, jointly promoting the development of related industries in Mexico and surrounding regions to shape a better future.

The post Haitian Mexico Open Day: a New Chapter of Regional Strategy appeared first on Haitian Group.

]]>Founded in 2010 and headquartered in Wuhu, Wuhu Anrui Optoelectronics Co., Ltd. (Anhui) has established four major production bases in Wuhu, Anhui; Hechuan, Chongqing; Taizhou, Zhejiang; and Birmingham, UK. As an enterprise integrating research, development, manufacturing, and sales, Anrui Optoelectronics focuses on technological innovation and information technology construction. After years of development, it has become a leading enterprise in the domestic automotive lighting manufacturing field and one of the fastest-growing companies in the history of the automotive lighting industry.

As early as 2018, Haitian and Anrui Optoelectronics began a close cooperation journey. We have jointly witnessed the birth of many “firsts” in China, witnessing Haitian’s technological progress and development in the field of large multi-component injection molding machines. Among them, the successful launch of the first 2100T vertical rotary two-color machine in China was a remarkable achievement of their cooperation.

This time, we have once again joined hands to achieve the successful mass production of the largest domestic vertical rotary 3300T multi-component machine. This achievement not only deepened the cooperative relationship between the two sides but also marked a significant milestone in their growth history.

Current Production of Changan Qiyuan E07 Front Full-width Light Bar at Chongqing Hechuan Factory

Current Production of Changan Qiyuan E07 Front Full-width Light Bar at Chongqing Hechuan Factory

Product dimensions: 1931*195*515mm

The 3300T vertical rotary two-color machine mainly produces large full-width light bars, with a maximum production capacity of 2.2 meters long, fully meeting the market demand for large-size, high-quality automotive lights.

Changan Qiyuan E07 Front Full-width light bar

As the largest tonnage multi-component equipment of the same series in China, the 3300T vertical rotary two-color machine has been developed based on Haitian’s mature and excellent two-platen technology platform, with a maximum mold rotating diameter up to 3100mm. It adopts dual servo motor control turntable technology, with a turntable bearing capacity of 28 tons. In addition, the equipment also has strong water and oil delivery capabilities to meet more complex and faster injection molding needs. The control accuracy of the turntable is as high as 0.005°, and the repeatability accuracy is up to ±0.5mm.

The successful birth and mass production of the 3300T vertical rotary two-color machine not only satisfied the need of domestic market but also provides customers with more possibilities for a high-performance, cost-effective alternative.

Building on this achievement, the collaboration between Haitian and Anrui?Optoelectronics once again highlights the innovative strength of Chinese manufacturing, fueled by new standards of quality and productivity. Looking ahead, Haitian and Anrui?Optoelectronics will continue to work together to drive development through innovation, promote technological advancement, and foster industrial upgrades.?

The post Haitian and Anrui Optoelectronics Deepen Cooperation appeared first on Haitian Group.

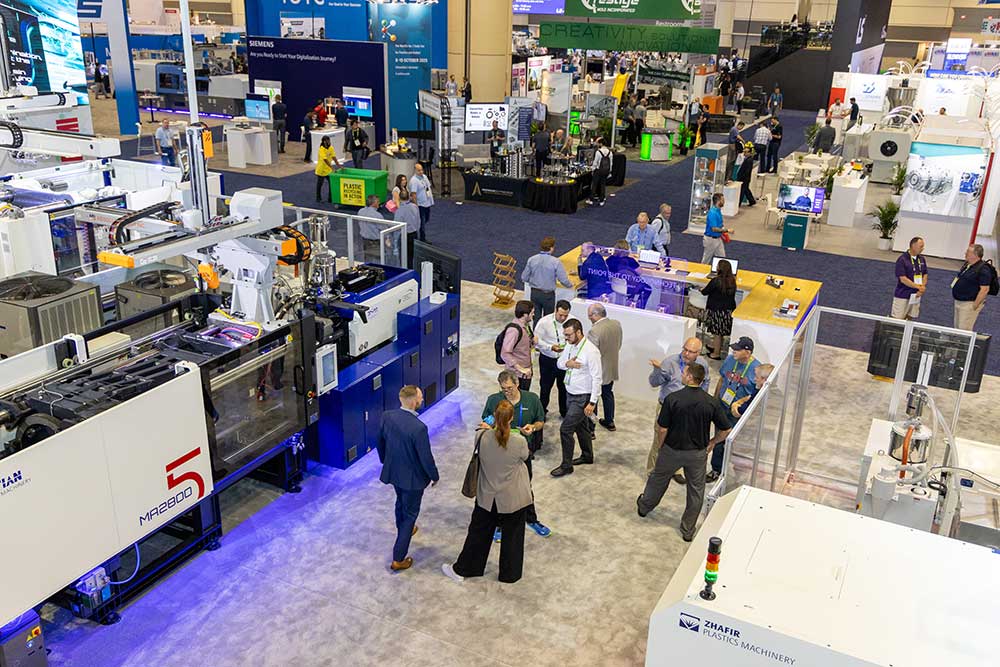

]]>On May 6th, NPE 2024, the Plastics Show, kicked off as scheduled at the Orlando Convention Center in Florida. Haitian International made a significant impact with the debut of our new fifth-generation technology at booth W943, showcasing our innovative capabilities.

Join us as we “cross oceans” to bring you live coverage from the event, diving into the day’s highlights and discussing new technologies, trends, and opportunities in the global plastics industry.

On the first day, Haitian International’s booth was bustling with activity. The first collective appearance of our new fifth-generation product matrix on the international market drew widespread attention, with many visitors stopping by to explore.

On-site, our smart, flexible, and sustainable specialized solutions attracted numerous customers and partners for enthusiastic consultations and discussions, offering new perspectives for efficient production for our international clients.

During the exhibition, Haitian International focused on consumer goods, automotive, and medical industries, presenting four core solutions—Haitian MA2800V/1350 energy-efficient consumer products industry solution, Haitian JU7500V/3450 space-saving automotive industry solution, Zhafir VE1200V-210hs clean precision medical industry solution, and Zhafir ZE1900V-300h flexible efficient medical industry solution. These innovative solutions stood out, bringing a feast of technology that’s second to none and fully powering up the “5”.

The four showcased core solutions, emphasizing energy conservation and efficiency, leverage multiple energy-saving technologies and high-precision controls to achieve energy savings of 20-40%. They also significantly reduce the machine’s footprint and cycle times, paving a new path for green manufacturing.

Moreover, the solutions extensively incorporate smart functions and hardware innovations, enriching the intelligent capabilities to digitally upgrade production processes, enhancing precision and stability in production, and enabling efficient, flexible integration across multiple systems.

These four solutions are all “Greenness + HT Xtend” showcasing the pinnacle of China’s injection molding technology, sparking an innovative wave of “technology going global”.

NPE 2024, the Plastics Show, will continue until May 10th. We look forward to your visit at booth W943 to join us at this international industry event and embark on the path of innovation with our fifth-generation technology!

The post NPE 2024 | Live from Day One: Leading the Wave of Technological Innovation appeared first on Haitian Group.

]]>On April 26th, the long-anticipated CHINAPLAS 2024 concluded successfully at the Shanghai National Exhibition and Convention Center. This exhibition was unprecedented in scale, covering a total area of 380,000 square meters. Moreover, the number of visitors from home and abroad broke historical records as well. With the number of exhibitors climbing historically to 4,420, global top-tier intelligent achievements were showcased.

During the four-day event, Haitian International focused on the rubber and plastics industry trends of high-end, intelligent, and green development, presented four industry-driven solutions. Leading technologies of efficiency and diverse application scenarios precisely responded to customer needs and market changes, creating a highly energetic atmosphere, with excitement continuously rising.

Among them, Haitian International’s brand-new fifth-generation products—VE600V-80h, VE1900V-430h, JU5500V/3450, MA2100F/580—all made their debut, presenting dedicated solutions for optics, medical, automotive, and packaging industries respectively. With highly efficient, energy-saving, and smart solutions, it provides more possibilities for the plastic processing industry.

From the utilization of multiple energy-saving technologies to the bundle of smart features based on Haitian’s “HT XTEND” platform, the new fifth-generation technology integrates numerous intelligent functions as well as hardware innovations. The new generation realizes the digital upgrade of the production process, empowering smart and efficient production.

Additionally, greenness is the foundation of high-quality development. The fifth-generation technology focuses on energy saving and efficiency improvement, achieving a 20-40% energy saving effect through the application of multiple energy-saving technologies and high-precision control, enhancing the accuracy and stability of the production process. While the equipment maintains robust performance, it also provides more possibilities for customers to achieve green manufacturing. Haitian International’s deep understanding of environmental protection and sustainable development is thus illustrated.

The exhibition ended successfully and we sincerely thank every visitor who attended the exhibition and are grateful for the trust and support of every customer. In the future, Haitian International will continue to provide the most competitive products and solutions for global customers and partners, strengthening their competitiveness in respective markets.

The post CHINAPLAS 2024 Ends Successfully appeared first on Haitian Group.

]]>During October 23-27, Haitian Group held a grand Factory Open Day for Overseas Customers in its Ningbo headquarters. Nearly 300 overseas customers and guests from 16 countries, including Germany, Czech Republic, Italy, France, Poland, Serbia, the Republic of Korea, and India, gathered in Ningbo to enjoy a feast of intelligent manufacturing and admire the original heritage and technological innovation of Haitian.

At the welcome ceremony, the Factory Open Day Tour officially kicked off.

In Haitian Digital Experience Center, the guests learned about Haitian’s development history, brand story, industrial distribution, future development, corporate culture, and sustainable development strategy in detail, and fully felt the achievements of “Digital Haitian”.

In the Intelligent Equipment Gallery, the fifth-generation product matrix of Haitian Plastics Machinery showed the guests the core strengths and diversified application scenarios of its new benchmarks for a new generation of energy-saving intelligent injection molding equipment. In addition, the latest products of Haitian Precision, Haitian Die Casting, Haitian Laser Machinery, as well as the one-stop intelligent manufacturing solutions of Haitian Smart Solutions, were also on display, giving the guests a deep understanding of Haitian Group’s perfect layout, system integration capabilities and intelligent manufacturing solutions in the field of machinery and equipment.

Quality and excellence are inseparable from strong manufacturing strength. During the factory tour, in the workshops of Haitian’s various business divisions, the guests immersed themselves in the intelligent manufacturing process, technology and efficient manufacturing system of Haitian. Here, advanced processing equipment, highly automated production processes, ubiquitous quality control and lean management provide quality assurance for the excellent performance of Haitian products, so that they can meet different needs of customers easily. At the same time, the guests witnessed the completion of an 8,800t super large injection molding machine on site, and spoke highly of Haitian’s excellent manufacturing strength.

With the end of the tour, the Factory Open Day for Overseas Customers came to a successful end. In the future, Haitian will continue to provide high-quality equipment support and comprehensive quality assurance for global customers and partners with its strong technical support and perfect manufacturing strength, so that “Haitian Machinery” will be able to explore new territories in the global market and continue to gain new vitality.

The post Factory Open Day Tour for Overseas Customers appeared first on Haitian Group.

]]>With a clamping force of 88,000 kN and an injection volume of 134,000 cm3, the servo-hydraulic two-platen machine Haitian Jupiter Series sets a new industry standard – a milestone in the development of giga injection molding machines.

In December 2022, the French company Belli SAS placed the order to manufacture this unusual large-scale machine. Haitian then put together a team of experts from various specialist areas to realize the project in close cooperation. At the end of October 2023, the JU88000 was successfully accepted by the customer at the Haitian Tongtu Road Division in Ningbo/China.

JU88000, probably the largest injection molding machine in the world

- Footprint of the giant: 27.2 x 9.5 x 6.1m

- Clamping platen: 5560 × 4920 × 1990mm; weight: 138t

- Injection unit: 13498 × 2514 × 2665mm; weight: 85t

- Machine bed weight of the clamping unit: 40t

- Machine bed weight of the injection unit: 19t

Customer Belli SAS develops and produces a wide range of plastic articles for home & garden, leisure and the environment. A few years ago, the customer had a two-platen machine with a clamping force of 33,000 kN built by Haitian. Managing Director Eric Chanal when asked what prompted him to order what is probably the largest and most powerful injection molding machine in the world: “I wanted to have no limits on the injection volume and told myself I would take the largest machine in the world so that I could produce very, very large parts.” The aim is to provide extremely large plastic containers as water tanks and rainwater storage tanks to support the water supply in Europe’s regions with little rainfall.

Haitian has taken on an unprecedented challenge with the development and construction of this machine and has mastered it with combined forces. Even during the design phase, the European team, led by Philippe Porret, Technical Director at Haitian International Germany, managed to exceed customer requirements. Among other things, they were able to significantly minimize the footprint and optimize the injection rate, enabling the machine’s performance to reach top international standards.

Mr. Zhang Bin, Vice President of Haitian Group, presented Eric Chanal with a model of the JU88000 as a commemorative gift

After extensive testing, the JU88000 received CE certification in September 2023. The commitment of the entire Haitian team to research, detail work and quality improvement played a crucial role in this significant push into new dimensions.

Haitian Smart mechanical arm VD-150ID

In parallel to the machine, Haitian Smart Solutions integrated the customized robot of the in-house brand “Hilectro”, type VD-150ID. It is also likely to set new standards in terms of size and performance.

Official machine acceptance ceremony at Haitian in Ningbo, China

Eric Chanal, the owner of Belli, personally traveled to Ningbo to inspect the machine and approve it during a formal acceptance ceremony. He was visibly impressed by his new giant: “Right from the start, Haitian was able to realize all my projects as I had expected. Nevertheless, one of my dreams has come true. Haitian really made it possible, and when I see Jupiter in front of me now, I still can’t believe it.”

The successful design and production of such a large injection molding machine and robot underlines Haitian International’s know-how and manufacturing power as a manufacturer. It also illustrates the enormous potential of the entire Haitian Group to single-mindedly break new ground and set new standards.

The post Injection molding machine with 8800t appeared first on Haitian Group.

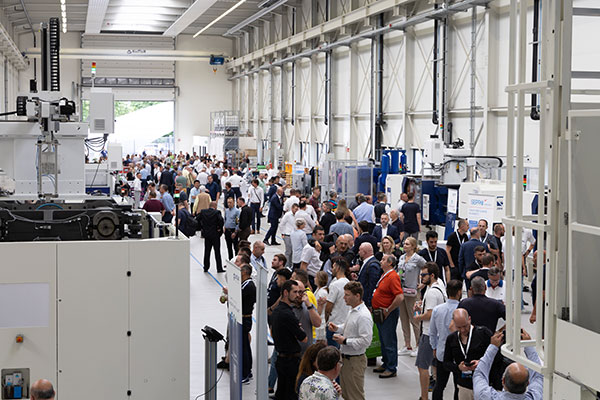

]]>The traditional yearly Open House of Haitian International Germany (June 20-22, 2023) in Ebermannsdorf, Bavaria, was a great success with more than 700 visitors from 13 countries. In addition to customers from all over Europe, some of whom had traveled a long way, our system partners and our local employees and their families, the mayor of Ebermannsdorf also came to pay his respects.

Once again in the focus of interest: Technology to the point. Our most important series and solutions for the most diverse requirements from medicine, logistics, consumer goods, packaging to automotive – such as clean or large-format production.

A total of 7 live applications on electric and servo-hydraulic machines could be experienced up close, partly equipped with linear robots of the “Hilectro” brand from Haitian Smart Solutions, the division within the Haitian Group responsible for automation and intelligent manufacturing solutions. Personal highlights for many visitors were the Jupiter and Mars as “SE” models. A more cost-effective version of Haitian’s energy-efficient servo-hydraulic machines.

18 system partners from Germany and Europe provided plenty to talk about among the visitors and in direct dialog with the exhibitors with their latest solutions. Other divisions of the Haitian Group even formed a trio of premieres: With two new CNC machines from Haitian Precision (at EMO Hannover in September) and a cold-chamber die-casting machine from the innovative “HDC Series” from Haitian Die Casting, both divisions showed that the Haitian Group has comprehensive solutions for intelligent manufacturing at the ready – all in Technology to the Point.

In the future, Haitian will continue to closely follow market developments in Europe, explore innovative products and application scenarios, and offer customers sustainable benefits through affordable solutions. Be it turnkey solutions for local needs or intelligent manufacturing solutions for the entire machine industry.

The post Open House 2023 in a New Format appeared first on Haitian Group.

]]>