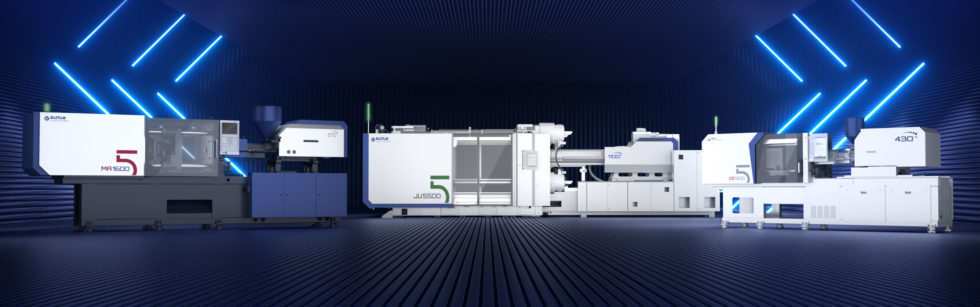

SMART TECHNOLOGY. FLEXIBLE INTEGRATION. SUSTAINABLE SOLUTIONS. THE 5TH GENERATION OF INJECTION MOLDING MACHINES FROM HAITIAN AND ZHAFIR SETS NEW STANDARDS.

The ideal of future-proof plastics processing combines quality and efficiency for sustainable solutions. Digital intelligence is the key to achieving this. Engineers and IT experts throughout the Haitian Group are working continuously to improve the core technology platform of our injection molding machines to meet these customer needs. The new generation of machines from Haitian and Zhafir combines numerous innovations at the highest level, paving the way for a new stage in intelligent and connected manufacturing.

At Chinaplas 2023 in Shenzhen from April 17 to 20, the complete 5th generation machine family – the VE5, ZE5, MA5 and JU5 – is presented to the trade for the first time.

SMART TECHNOLOGY

Generation 5 intelligence marks a new level of excellence. Through the use of AI algorithms and the latest sensor technology, we are achieving intelligent optimization of production processes and giving our machines the ability to self-recognize, self-adapt, self-decide and self-reconstruct.

What’s more, the G5 offers many of these smart features as standard equipment.

?

SMART FEATURES AS STANDARD

HT Energy 2.0

Intelligent Energy Management 2.0 as standard. Display and management refinement of energy consumption. Establishment of an energy-saving ecosystem.

HT Clamp 2.0

Intelligent opening and closing 2.0 as standard. Self-learning algorithm for precise mold movements.

HT Lubricate

Intelligent lubrication as standard. Multi-data algorithm for intelligent lubrication control and intelligent setting of lubrication parameters.

HT Analysis

Intelligent diagnostics and support. 2D code alarm and online help.

?

FLEXIBLE INTEGRATION

The intelligent Injection Molding Machine Generation 5 is equipped with a wide range of flexible integration functions as standard. Open interfaces support efficient connection with peripherals, automation units, etc.

With upstream and downstream data from the industrial value chain, an integrative production ecosystem is created that generates extensive information benefits for plastics processors. From plant status and production schedule, process control and quality traceability to full life cycle management including energy consumption, decision analysis, etc.

?

SUSTAINABLE SOLUTIONS

As one of the market leaders in the plastic injection molding machine industry, Haitian International sets clear priorities in fulfilling its social responsibility, protecting the environment, and conserving resources through research & development.

We continuously develop energy-saving and consumption-reducing technologies, promote upgrades of energy-saving equipment, reduce carbon emissions, and provide technological innovations and efficient solutions for degradable and recyclable materials.

?

EFFICIENT COMPETITIVE ADVANTAGES

With our years of experience and smart innovations, we work to further reduce our customers’ operating costs, thereby increasing their production efficiency. Moderate acquisition costs for Haitian and Zhafir machines also remain among our core criteria. This will continue to be the case in the future. State-of-the-art production plants around the world, in-house manufacturing of core components, R&D in close cooperation with Haitian Drives Systems and Haitian Smart Solutions: Haitian International stands for affordable innovations and turnkey solutions from a single source.

Haitian International at Chinaplas 2023

Hall 12, 12G31

The post CHINAPLAS 2023: THE WORLD PREMIERE OF THE 5TH GENERATION appeared first on Haitian Group.

]]>More and more plastic wastes are dumped into the natural environment, threatening human health and sustainable global development. So what can we do to make plastic clean and recycled? In CHINAPLAS 2023, Haitian actively explored into the recycling journey of plastics, so as to provide technological innovation and green solutions for the development of plastic recycling economy, and promote the whole life cycle management of plastics.

1. Background

According to the report?Global Plastics Outlook: Policy Scenarios as of 2060?released by OECD in 2022, the global amount of use of plastics in 2060 is expected to triple that in 2019, and plastic waste will also increase by nearly three times. About 8-12% of global plastics are recycled, and most of the rest are dumped in landfills or discharged into the environment, bringing serious pollution and health problems to the environment.

In this context, it has been an important goal for various countries to develop circular economy and explore new green and low-carbon paths. In order to increase the recycling rate and promote the circular plastic economy, countries have begun to introduce targets to encourage or even require the use of recycled plastics, so that waste plastics can be reborn in a new scenario with economic, environmental and social values.

2. Recycled plastics in China

China is one of the world’s largest consumers of plastic and a major producer and consumer of recycled plastic. With the improvement of environmental protection awareness and the support of government policies, the market demand for recycled plastics in China shows a steady growth. At the same time, consumers’ demand for green and environmental protection products is increasing, and recycled plastics are more and more widely used in packaging, home appliances, automobiles, plastic products production, building materials, textiles and other fields, further promoting the quantity demand growth of China’s recycled plastics market. In addition, the price of recycled plastics in China has a certain advantage compared with the international price, so recycled plastics are also attracting more and more attentions from enterprises and consumers, and the capacity of China’s recycled plastics industry is expanding.

3. Source and application of recycled plastics in China

According to the statistics and calculation of the amount of waste plastics recycled in 2021, the main sources of waste plastic include electrical and electronic products, waste lunch boxes, waste automobile plastics, waste PET, and so on.

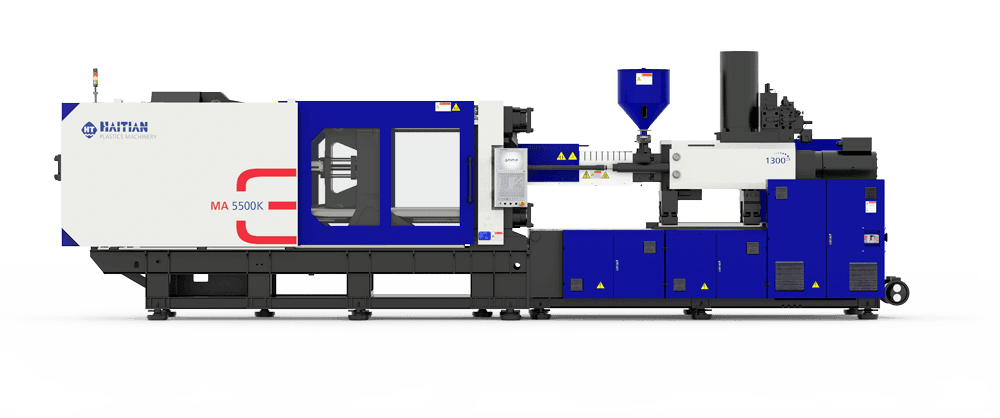

During this session of the Chinaplas exhibition, Haitian will use recycled ABS as raw material on Haitian MA5 to solve the pain points in production, show Haitian International’s sustainable development strategy and technological innovations in circular economy and carbon and emission reduction, and drive the high-quality development of “circular economy”. The 100% recycled ABS material will be used this time, which is from Shanghai Re-mall Environmental Protection, a professional high-quality supplier of recycled plastics.

4. Outlook

Plastic circular economy refers to an economic model that reduces resource consumption and environmental pollution by recycling waste plastics to achieve sustainable development. In the future, the development of plastic circular economy will require the active participation and joint efforts of the government, enterprises and all parties in society to maximize the utilization of resources and environmental protection.

The post JOURNEY TO THE RECYCLED PLASTIC appeared first on Haitian Group.

]]>Chint Group, founded in 1984, is a world-renowned intelligent energy system solution provider. Under the new wave of industrial digitization, grasping the new development opportunities of digital intelligence and carbon peaking and carbon neutrality goals, Chint has continuously deepened the transformation and upgrading strategy. In order to scientifically and steadily promote the implementation of the digital intelligence development strategy, Chint will continue to build a comprehensive, high-quality highly skilled talent team.

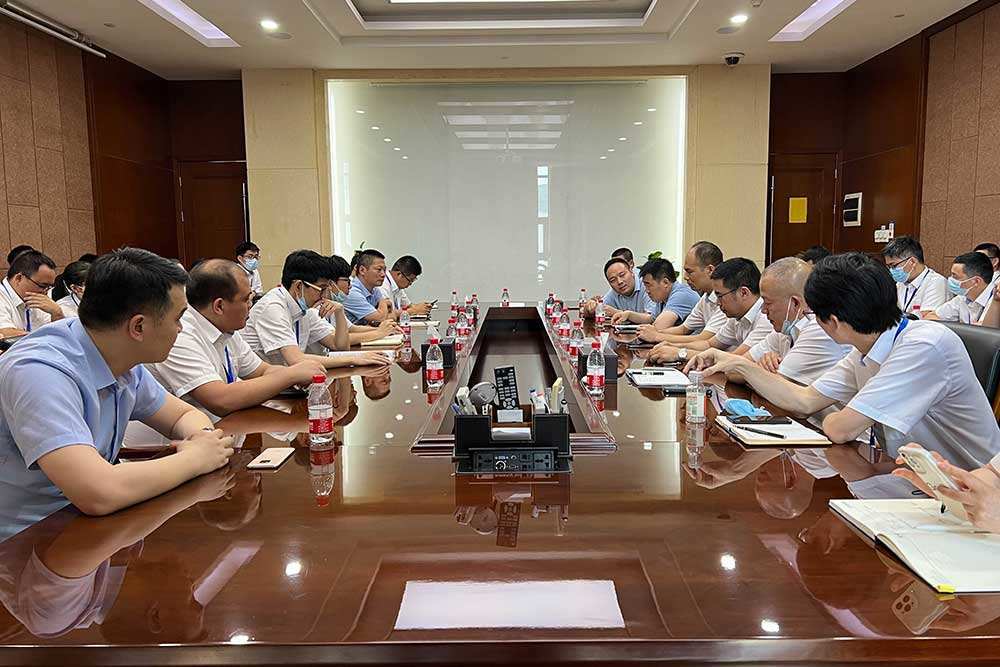

On July 21, 2022 – the opening month of Haitian factory – a special visitor, Zhejiang Chint Electrics Co., Ltd. (hereinafter referred to as “Chint”), a subsidiary of Chint Group, came to Haitian headquarters for a special customer exchange meeting. In this exchange meeting, adhering to the concept of sincere service and focusing on the actual needs of Chint, Haitian committed to the “one plan for one enterprise” strategy to create zero distance communication and services, and realizing the upgrading of cooperation between the two parties.

Through continuous communication with customers in the early stage, Haitian deeply explored the demands of Chint and customized the content of this exchange session, including process technology, equipment operation and maintenance, lean production, production management, and digital construction. During the factory tour, the rich exhibition solutions and one-stop solutions for injection molding workshops left a deep impression on the guests.

At the exchange meeting, the heads of various departments of Chint put forward many questions and opinions on production technology and equipment use, while the technical experts of Haitian Group gave detailed answers and introductions to each question, leading to an enthusiastic on-site discussion atmosphere. Subsequently, the two sides conducted in-depth exchanges on building a full-life-cycle collaborative intelligent manufacturing system and a green manufacturing system. After deeply communicating and learning more about Haitian’s unique “8 + 16” intelligent manufacturing model and digital management platform, the leaders of Chint expressed their deep appreciation and expressed that it is worth learning and using for reference.

Doing a good job in the transformation and upgrading of digital intelligence and green development requires more technological innovation and production practice. In the future, Haitian will continue to be driven by technological innovation to promote productivity changes in various fields, continue to output high-efficiency digital productivity to customers, solve practical problems faced by customers, and contribute to the transformation and upgrading of the industry and green development!

The post Haitian & Chint|Thematic Exchange Meeting – Grow together with Customers appeared first on Haitian Group.

]]>A bigger booth, more exhibits, more room for smart solutions: At its almost 700 sqm booth in Hall 15/A57, the global market leader will showcase the benchmarks of its broad technology spectrum for a wide range of applications in key sectors of the plastics processing industries. Besides two European machine premieres, Haitian International will also present new developments and strategies within the Haitian Group at K 2022.

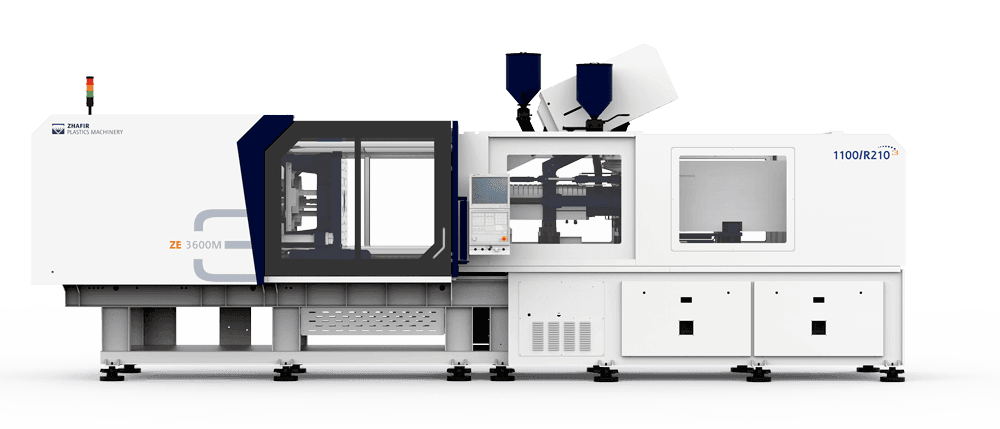

Under the motto “Smart Technologies – Flexible Integration – Sustainable Solutions,” Haitian International is clearly positioning its Zhafir and Haitian brands for the future and, together with various partners, will showcase live applications from different industries and application areas. Haitian International will present a total of five exhibits at K 2022. The broad portfolio of electric series from Zhafir Plastics Machinery – whether as an all-electric solution, with integrated hydraulics or as a hybrid solution – will be represented by three machines.

In addition, Haitian International is communicating the synergies within the Haitian Group. Haitian Smart Solutions, also a member of the Haitian Group, will be presented for the first time in Düsseldorf at a European trade show as an accomplished integration partner.

New technologies

While the current machine portfolio already covers almost all requirements in the plastics processing industry, Haitian International is pushing ahead with new developments of its machine series. In addition to two European machine premieres showcasing the wide range of applications for Haitian machines, Haitian International will be exhibiting for the first time intelligent machine functions that enable plastics processors to achieve additional energy savings and more efficient processes. For instance, an intelligent energy management function. Furthermore, the company will introduce other features such as intelligent process optimization, plasticizing efficiency or clamping force optimization and thereby give an outlook to the next machine generation. Haitian International’s declared goal: To offer smart features as a standard feature at no extra charge.

Flexible integration

Standardized interfaces and open system integration are the fundamentals for maximum flexibility in terms of connectivity. Thus, Zhafir and Haitian machines offer processors almost unlimited freedom in their choice of integration partners. Accordingly, several system partners will be integrated into the machine concepts at K 2022. In the MES area, in addition to Haitian Smart Solutions’ own “GoFactory”, another MES partner will be presented specifically for the European market. All 5 exhibits will be connected to both systems.

Industry-oriented, sustainable solutions

Energy efficiency has always been a key aspect in the development of all Haitian machines. In this regard, sister company Haitian Drive Systems confirms its value as a co-innovation driver by developing and providing energy-efficient drives. Since 2006, these are used as standard in all machine series of the Zhafir and Haitian brands.

In the future, Haitian will intensify the development of industry-oriented and sustainable solutions. With the European premier of the Haitian Mars K Series, Haitian shows a machine not only ready for fast cycles, but also an effective solution for the processing of recycles and sustainable materials.

The K2022 exhibits at a glance

Medical: An electric Zhafir Zeres Med Series with 1,200 kN and medical package, will demonstrate an economical cleanroom solution made from PP with a laminar flowbox from Max Petek.

Commodity: An electric Zhafir Zeres Multi Series with 3,000 kN, presented as an R-version (piggyback) will be integrated into a production cell with in-house robotics of the Hilectro brand. The ZE-M produces a tape measure housing made from ABS/TPE.

Automotive: The electric hybrid Zhafir Jenius Series with 3,600 kN, is producing an automotive part that is removed with a “Success 33” from Sepro.

Logistic: A servo-hydraulic Haitian Jupiter with two-platen technology and 4,500 kN produces a fruit box made from a material compound HDPE and TetraPak recyclate. The application is integrated into a manufacturing cell with in-house Hilectro robotics.

Packaging: The servo-hydraulic Haitian Mars K Series with high injection performance of up to 1,000 mm/s is celebrating its premiere in Europe. It will produce a food container with IML, integrated into an automation system from Hilectro.

HAITIAN INTERNATIONAL AT K-SHOW: HALL 15 / STAND A57

Zeres M Series – the electrical multi component solution in R-version

Zeres M Series – the electrical multi component solution in R-version

Haitian Mars K Series – the servo-hydraulic solution with injection speed up to 1000 mm/s

The post New developments and European premieres at K 2022 appeared first on Haitian Group.

]]>

As usual, the wonderful content arrived as scheduled. This year, Haitian Germany showed people the injection molding technology with “Technology to the point””, efficient industry solutions and related automation.

At the event, Haitian International Germany showed its mature injection molding equipment and comprehensive strength, covering auto parts, thin-wall packaging, cosmetics, daily necessities and other industries, to fully demonstrate Haitian’s ability and confidence to be close to European customers and meet the European market. The audience also had “zero” contact with Haitian and ZHAFIR product families at the plant to know Haitian’s rich range of manufacturing processes.

At the same time, Haitian International Germany also provided a series of interactions during the open house, including technical information release, factory visit, industry lectures and discussions and other activities, and our partners also showed their own solutions on site.

Haitian has been deeply engaged in the European market for many years. With its profound technological accumulation and localization advantages, it has joined hands with partners to respond to customers more efficiently and to provide them with all-round support such as R& D, manufacturing, training, services and overall project management, as well as more ingenious and customized solutions, so as to create outstanding value for European customers.

The post A Tour in Haitian International Germany Open House appeared first on Haitian Group.

]]>On July 2, Haitian Eastern Operation Center Southeast China officially opened in Dongguan, which is not only an important step for Haitian to consolidate the layout of South China and deeply cultivate regional development, but also will bring high-standard and high-quality products and services to local customers and actively empower the industry.

PLAN A REGION FROM A GLOBAL PERSPECTIVE, AND SERVE THE GLOBAL WITH A REGION

Haitian Eastern Operation Center Southeast China, opened and operated by Haitian Plastics Machinery Group South China Company, is located in the core circle of high-speed logistics in Dongguan. The Center is built into a three-floor single comprehensive building integrating sales, application, service and office, with a total area of 1,500m2. The first floor is mainly used for the machine exhibition, customer training, mold testing, the second floor is used for popular sample display, conference, training and office and the third floor is used for both comprehensive services and product applications. At the same time, the Center is equipped with a green screen live streaming room to meet all kinds of live streaming activities and create a new model of the traditional machinery industry.

In addition to the hardware configuration, the Center has a professional application engineer team to fully meet the diversified customer needs from pre-sales technical support to in-sales and after-sales service.

At the opening ceremony, leader representatives including Shen Li, General Manager of Haitian Machinery Guangdong Co., Ltd. and Haitian Plastics Machinery Guangzhou Co., Ltd., Xu Haihui, General Manager of Haitian Plastics Machinery Group South China Company and Miao Longzhen, Deputy General Manager of Haitian Plastics Machinery Group South China Company attended the ceremony and delivered speeches.

Along with the applause, all leaders and guests took to the stage for the ribbon-cutting ceremony to witness the grand opening of Haitian Eastern Operation Center Southeast China. After the ribbon-cutting ceremony, painting the eyes of the dancing lion, meaning auspicious, brought the site atmosphere to a high point.

Plan a region from a global perspective, and serve the global with a region. Dongguan, an important manufacturing area in Guangdong-Hong Kong-Macao Greater Bay Area, has strong manufacturing strength, complete industrial system and obvious geographical advantages. Therefore, the establishment of Haitian Eastern Operation Center Southeast China in Dongguan will not only further improve the sales and service layout in South China, but also radiate to cities such as Dongguan, Shenzhen and Huizhou on the East Bank of the Pearl River, thus bringing more convenient and intimate product service experience and overall solutions to local customers, and greatly improving the comprehensive service capacity of Haitian Eastern South China.

ALL IS READY

With a broad market space, South China is the key strategic market and development center of Haitian. In March last year, the Haitian Comprehensive South China Headquarters Project was launched in Shunde, Guangdong, opening the “double center” model of Ningbo and South China. The Eastern South China Operation Center is another subsidiary of Haitian in South China, which will further improve the regional service system of Haitian in South China.

All is ready.?As a key component for Haitian to deeply cultivate in the South China market continuously, Haitian Eastern Operation Center Southeast China will complement each other and gather a strong joint force. With more meticulous and considerate service, Haitian will bring the ultimate product experience to more customers in South China, deploy more high-quality projects in South China and work with local customers to develop and create the future together.

The post HAITIAN EASTERN OPERATION CENTER SOUTHEAST CHINA SETS SAIL appeared first on Haitian Group.

]]>The electric vehicle market for passenger cars is growing quickly with increasing consumer demand. As a highlight of the electric vehicles, optical parts including long light guides have become a design trend in the automotive industry. Coming in many variations and with different visual effects, the lamps have tremendous design flexibility and also enhance the safety advantage.

LIGHT GUIDES: A HIGH-TECH PRODUCT

The light guides – made of transparent plastics – is the light-emitting part of the car light. It has the advantages of high energy efficiency, a long lifespan, dimming capability, etc. It can effectively reduce the number of lamp bulbs and further achieve the goal of automotive light-weighting.

TECHNICAL CHALLENGES

Being an optical product, the manufacture of light guide strips for headlights has strict optical standards and appearance requirements. To meet the conditions like light transmission, thermal stability, shape accuracy, surface gloss, and haze, the material of the optical part issues high viscosity and moisture sensitivity as the disadvantages to overcome. Advanced injection molding technology during manufacturing, in other words, the stabilization of processing, is essential for those optical parts. Otherwise, defects may appear. It must also be mentioned that the suitable combination of the clamping and injection components is a predominant factor for the technical challenge caused by the thick mold and low filling volume.

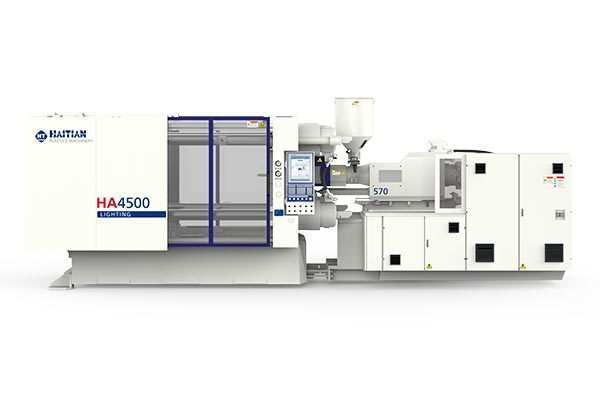

HAITIANS’ SOLUTION FOR LIGHT GUIDES

In view of the characteristics and production difficulties of light guide strips, Haitians special machine solution can meet the production of long light guide strips (headlight guide, through-tail light guide, ambient light) and at the same time, can be compatible with other products to the greatest extent.?Key components have been upgraded to reduce manufacturing risk.

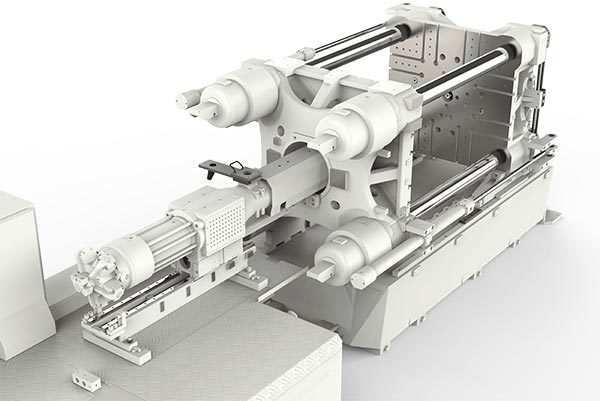

Machines are equipped with PC special plasticizing components. Screw, barrel and other core parts are specially treated to meet the application requirements. Based on our Jupiter machine platform, the mold capacity and thickness have been increased.

The full closed-loop injection function helps low-speed injection molding and solves the problem of stability in low-speed condition. According to the physical laws of the light transmission, the plastics in the cavities of the thick-walled mold has to be not only filled continuously but also be smooth on the surface to make light transmission successful.

LONG LIGHT GUIDE

As a special optical part, the long light guide is lightweight with a length exceeding 1500mm. There have been several issues, such as the combination of clamping and injection components, plasticizing unit, and molding technology. It is generally believed that molding technology plays an important role which maintaining stability during the process based on the relevant tests and analysis.

So far, most vehicles on the road are equipped with LED lighting and light guides. With the popularity of vehicle intelligent driving technology, light guides will be more frequently used in the automotive exterior decoration. Haitian will continue to take customers and the market as the center, continue to empower the automotive industry, consolidate the core competitiveness of high-quality development, and jointly enter a new stage of development.

The post HAITIAN LIGHTING SOLUTION FOR THE AUTOMOTIVE INDUSTRY – EFFICIENT AND RELIABLE SOURCE OF LIGHT appeared first on Haitian Group.

]]>Haitian Huayuan Japan Machinery Co, Ltd (hereinafter referred to as Haitian JP) was established in 2016. The company, which was previously located in Odawara City, Kanagawa Prefecture, Japan, moved to Nagoya City Minato-ku, Aichi Prefecture, on April 1, 2022 to officially operate.

Aichi Prefecture is located in central Japan and is the fourth largest province in Japan with a population of approximately 7.5 million people. It is one of Japan’s leading industrial regions, with many automotive companies – led by Toyota Motor Corporation – accounting for 14.9% of the nation’s total sales of 47.9 trillion yen (about $400 billion) in finished goods shipments – the highest in Japan for 43 consecutive years.

Aichi Prefecture is famous for its unique local culture, including stewed dishes using soybean miso such as Miso Udon and Miso Pork Cutlet. Nagoya City is located in the northwestern part of Aichi Prefecture, with a total population of 2,284,000 people, and is the capital of Aichi Prefecture. It is also the center of the Nagoya Metropolitan Area, one of the three major metropolitan areas in Japan. About 15km south from Nagoya Castle – a famous sightseeing spot – you will come to the new office of Haitian JP.

At present, we are exploring the Japanese market to meet our customers. With the support of Japanese agents, we provide safe and high-quality services for customers in the Japanese market through a professional team.

In addition, there is a test machine on the 1st floor of the new office for customers to test applications, and we look forward to welcoming customers interested in Haitian injection molding machines. We will continue to enrich and improve Haitian JP’s business functions and strive to increase the contribution of Haitian machines in the Japanese market.

In the future, Haitian will continue to intensively cultivate the Japanese market and build a strong global market presence by enhancing the global competitiveness of our products and brand service capability as well as providing customized solutions for customers.

The post HAITIAN HUAYUAN JAPAN BRANCH OPENS NEW BUSINESS LOCATION IN NAGOYA appeared first on Haitian Group.

]]>