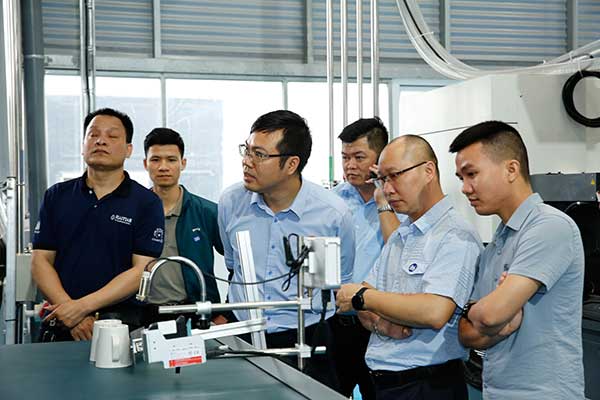

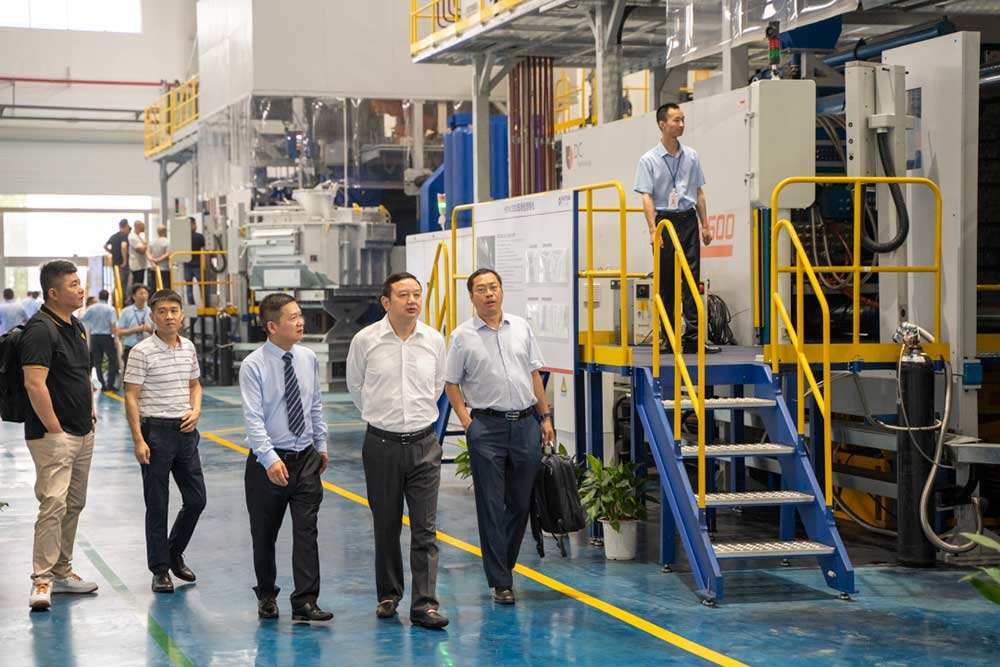

Recently, the Haitian Vietnam Haiphong Application Service Experience Center held its first factory open day since its opening. This open day attracted Haitian customers from the northern part of Vietnam, as well as some from the southern region. Through in-depth visits, participants got a close and comprehensive view of the equipment production details and application solutions. Visitors experienced “zero distance” the fully facilitated and comprehensive service capabilities of the new Haiphong Application Service Experience Center, allowing craftsmanship to be visibly appreciated.

During the open day, through the deep integration of injection molding technology and application scenarios, Haitian Vietnam showcased 7 sets of solutions. These solutions included the latest fifth-generation technology released by Haitian International, as well as currently popular models in the local market and NIIGATA electric machines from Niigata Machinery, covering popular industry applications in the local market and providing diversified solutions to meet the varied needs of different customers.

Among them, the MA2500V, as a major debut of the fifth-generation technology, demonstrated characteristics of smart innovation, energy efficiency, and performance upgrades, bringing a refreshing technological experience to the attendees; the JU5500SE, targeting the automotive parts market, provided a manufacturing solution for electric vehicle parts, showcasing its compact structure and size advantage over other machines of the same tonnage; the Haitian HA4700PET model, paired with Haitian servo machinery hand for part retrieval, demonstrated the production of wide-mouth bottle preforms on-site, attracting visitors to watch and receiving unanimous praise and recognition.

In addition to the rich injection molding solutions, customers also experienced on-site the exciting display solutions of other industries under the “Haitian Group”, including smart factory management systems, CNC machine tools, die-casting machines, etc., appreciating Haitian Group’s comprehensive industrial chain layout in the machinery equipment field.

Vietnam is an important part of Haitian Group’s “Five-Five Strategy” plan. Thirteen years ago, Haitian established its first factory in Binh Duong, Vietnam. With the official commissioning of the Haiphong Application Service Experience Center on December 31, 2023, Haitian has formed a service network in Vietnam that “connects the north and south, reaching throughout Vietnam,” capable of providing local and surrounding customers with one-stop complete solutions and comprehensive service support focused on machinery equipment.

High-quality products and efficient services are crucial for Haitian to deeply and solidly penetrate the Vietnamese market. It is hoped that this open day event will provide broader intelligent manufacturing development ideas for a wide range of Vietnamese customers and partners. In the future, Haitian will continue to deepen its layout in the Vietnamese market, continuously improve the local industry service system, provide strong support for localized delivery and service, enhance Haitian’s response speed and service capabilities in Vietnam and Southeast Asia, create a considerate user experience for local customers, and generate more value.

The post Haitian Vietnam Factory Open Day, Creating a New Future Together appeared first on Haitian Group.

]]>From November 5 to 10, 2022, the 5th China International Import Expo (CIIE) is held in Shanghai. On November 7, during the CIIE, Panasonic Corporation of China and Haitian Plastics Machinery Group signed a strategic cooperation framework agreement.

The signing ceremony was attended by Tetsuo Honma, Global Vice President and General Representative of Panasonic Holdings Corporation in China and Northeast Asia, Li Xuliang, Deputy Director of Production Strengthening Center of Panasonic Corporation of China, General Manager Hu Jiehua, Deputy General Manager Yoshiharu Kunisei, Deputy Director Wang Yonghua of Panasonic Appliances Washing Machine (Hangzhou) Co., Ltd. Zhang Bin, Executive Vice President of Haitian Group and Executive Vice President of Haitian Plastics Machinery Group, Hu Yongkai, Regional Business Director of Haitian Plastics Machinery Group, General Manager Chen Shengwei and Deputy General Manager Chen Yihan of the Regional Sales Company, and other leaders.

At the ceremony, Zhang Bin, Executive Vice President of Haitian Group, said: “the cooperation between Panasonic and Haitian Group began in 1995. Our long and sincere cooperation has forged a deep friendship between us. The signing of this strategic cooperation framework agreement will provide new opportunities for Panasonic and Haitian to carry out comprehensive cooperation. We will actively build a new platform for our collaborative development, raise the level of strategic collaboration, and continue to provide Panasonic with high-quality products, efficient services, and excellent customer experience.”

According to the agreement, the two sides will follow the cooperative spirit of “l(fā)ong-term cooperation, resource sharing, mutual benefit, stability, permanence, efficiency and quality” and form a deep strategic cooperative partnership to embrace new opportunities in the new era hand in hand, provide consumers with more convenient and high-quality services, and create new value for each other.

It is reported that Panasonic has participated in the CIIE for five consecutive years. Its theme this year is “Environment”. The positive contributions made by Panasonic’s overall value chain to carbon dioxide emission reduction is introduced.

In order to realize green development, in the future the two sides will carry out in-depth cooperation in several projects such as energy-saving hydraulic injection molding machine and its intelligent manufacturing solution, energy-saving, environment-friendly, high-quality and high-precision electric injection molding machine and its intelligent manufacturing solution, and optimization of production processes. The two sides will work together to save energy and reduce emissions in the process of injection molding, make positive contributions to environmental protection and sustainable development, and enable each other to gain more favorable market competitive advantages.

The post Haitian Plastics Machinery and Panasonic Sign a Strategic Cooperation Agreement to Jointly Build a Path to Green Development appeared first on Haitian Group.

]]>Accelerated growth of new energy vehicles

In recent years, as the market demand for new energy vehicles has exploded and sales have continued to reach record highs. In 2022, the new energy vehicle industry is still developing rapidly. In the first quarter, the total sales volume reached 1,004.2 million RMB, and the penetration rate increased to 21.1%, showing an accelerating upward trend.

According to the statistics of the Ministry of Industry and Information Technology of the People’s Republic of China, 10.33 million new energy vehicles have been promoted in China, making China an important force leading the development of the global new energy vehicle industry. The automotive industry is ecologically booming, and the competitive market among major new energy vehicle brands will expand.

Haitian helps new energy vehicle brands to grow

New industries are changing day by day and the formation of new markets is accelerating. Under the wave of new energy vehicles, also the injection molding industry has seen a new development direction. Plastic injection-molded products are widely used in the field of new energy vehicle manufacturing because of their light weight, good electrical insulation, corrosion resistance and other characteristics.

While demand is growing, the market puts forward higher requirements for the quality of parts. Facing the increasingly fierce competition in the market, how can injection molding machines help car companies to further strengthen their advantages in the manufacturing end?

As the industry leader and technology pioneer of domestic plastic machines, Haitian has achieved great results in the process of cultivating the field of new energy vehicles and obtained a number of national invention patents and utility model patents, filling the gap in the industry and exploring more ways for new energy vehicle enterprises to improve quality and efficiency.

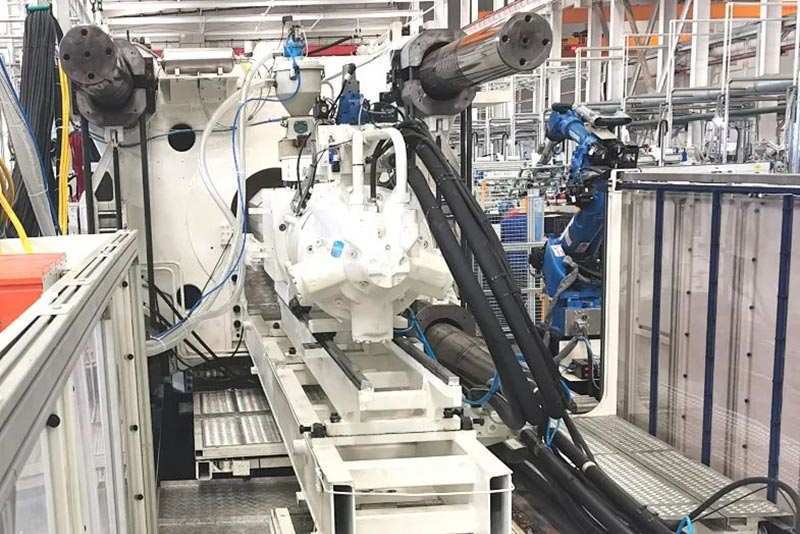

In the multi-component field, Haitian continues to increase technology research and development in response to the lightweight development trend of new energy vehicles and takes the lead in launching the industry-leading two-color lamp bi-injection molding solution to create a more competitive lighting solution with leading quality, and help new energy vehicle brands to develop and grow.

Haitian multi-component vehicle lamp bi-injection molding solution

Based on the popular?JUIII?platform of Haitian and relying on the profound accumulation of multi-component molding technology, the?bi-injection molding solution?provided for the new energy vehicle industry is more flexible and efficient. It can easily handle the injection molding of high-quality two-color lamps, effectively improve the quality and appearance conditions of lamps, realize cost reduction and efficiency increase and bring significant cost and technical advantages to new energy vehicle manufacturers.

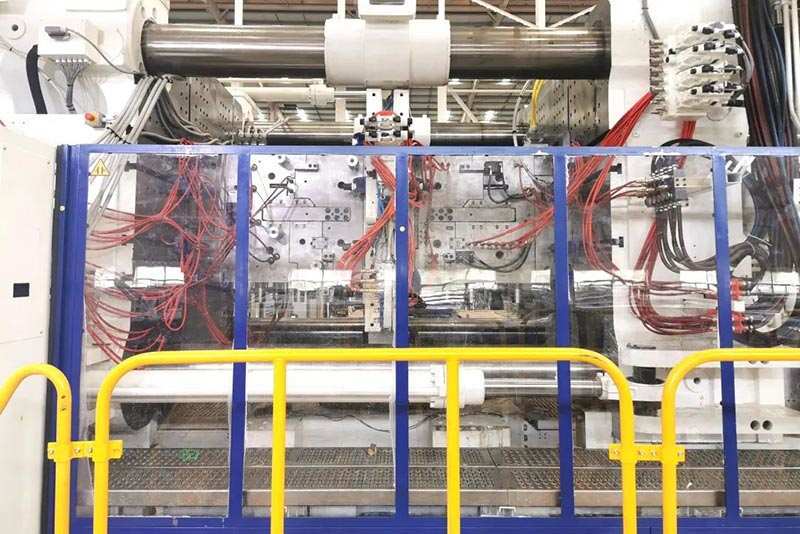

Haitian JU24000M/6730-A6730, with?a mold locking force of 2,400T, is the first 2,400T bi-injection model in China. The whole machine is designed according to the horizontal rotary table technology. The main/auxiliary injection device is installed on the side of the movable and fixed mold plates respectively, where the movable horizontal rotary table or the rotating mold is supported by its own base frame, making the mold more compact. It can be used as a multi-purpose machine or as two single-color injection molding machines to meet the customer’s demand of producing large two-color products.

JU24000M/6730-A6730

Equipment features:

- The advanced horizontal rotation technology can achieve double capacity in a smaller mold frame and significantly shorten production cycle time and reduce electricity and water costs.

- Larger mold holding space and stronger load-bearing capacity of rotary table facilitate stable production of large molds.

- Reasonable mold cavity distribution is beneficial to mold structure design, and is suitable for the production of each large-scale multi-component parts.

- Flexible design realizes more freedom and functional integration in the field of new energy vehicle manufacturing.

Applications

- Model: JU24000M/6730-A6730

- Product: Headlight mask (SA3F)

- Single weight: 690 g

- Number of cavities: 2

- Raw material: PC

- Industry: Automotive industry – lamp components

- Features: Two-color bi-injection process

Molding the future together

Recently, a number of Haitian multi-component bi-injection molding machines have been successively installed in domestic new energy vehicle manufacturing plants and put into production. In the future, Haitian will continue to cooperate with major new energy vehicle manufacturers to continuously meet the needs of the industry, jointly build a more sustainable industrial ecology, and drive the new energy vehicle industry onto the fast lane of green development.

The post HAITIAN’S MULTI-COMPONENT LAMP MOLDING SOLUTION HELPS THE DEVELOPMENT OF NEW ENERGY VEHICLES appeared first on Haitian Group.

]]>HAITIAN INTERNATIONAL RECORDS SALES OF RMB 16,018.3 MILLION IN 2021 +++ A 35.7% INCREASE OVER 2020 +++ TOTAL SALES OF MORE THAN 56,000 MACHINES +++ ESG REPORT PUBLISHED IN 2022

March 22, 2022, Hong Kong. Haitian International Holdings Limited (“Haitian International”, together with subsidiaries and affiliates referred to as the “Group”; stock code: 1882), one of the world’s largest manufacturers of plastic injection molding machines, announces its annual results for 2021 (January 1 to December 31, 2021).

Global economy and business performance

Due to greater COVID-19 vaccination coverage, easing monetary and fiscal polices and increasing demand in various industries the global economy showed an overall positive trend in 2021. At the same time increased logistic costs, inflation, supply shortages and energy crises have still contained the global economic recovery. China’s domestic economy, benefiting from its strong manufacturing industry and loose investment and export policies remained stable overall.

For Haitian International the strong demand from domestic and overseas downstream industries in 1HY2021 and overall stability in 2HY2021 contributed to the remarkable results in 2021. In 2021 the sales of the Group amounted to RMB16,018.3 million, representing an increase of 35.7% compared to the previous year. A total of over 56,000 machines were sold, marking not only a historic overall record high, but also emphasizing the great recognition of the Groups products within the market.

Domestic sales amounted to RMB 11,088.2 million, representing an increase of 33.9% compared to the same period last year. Haitian’s annual exports exceeded 10,000 units for the first time, with total overseas sales reaching RMB 4,930.1 million. This represents a significant increase of 40.1% as compared to the same period last year, further increasing the overseas market share. The company recorded a notable increase in sales in key overseas markets such as North America and Southeast Asia, as well as a steady increase in sales in regions such as Europe and South America.

Benefiting from the Group’s application driven product developments and thorugh the overall growing demand in 2021, sales of the Haitian Mars Series – the Group’s main product – continued to increase steadily, reaching RMB 10,944.0 million for the year, representing a year-on-year increase of 33.2%.

Following the recovery of high-end industries and also the automotive sector both in China and overseas, sales of the Zhafir Electrical Series’ and the two-platen technology Haitian Jupiter Series reached an all-time high. They increased significantly by 44.3% year-on-year to RMB 2,077.5 million and by 54.8% to RMB 2,017.3 million, respectively.

Outlook and future strategy

Haitian International has always emphasized a global strategic focus. In China, the company will drive its corporate and market development in the future with two headquarters, in Ningbo as well as in Shunde, South China. The Shunde site is on schedule to be in the first phase and is expected to start trial production in the second half of 2022.

At the same time, Haitian will continue to strengthen its global footprint. In regard to the projected high logistics costs, the Group will continue to develop overseas regional headquarters and expand overseas assembly and trade-oriented factories into integrated regional centers combining research and development, manufacturing, assembly, application, sales and service to localize production worldwide.

In parallel, the company will continue to expand R&D of application driven solutions for various industries to enhance the competitiveness of its products. The further implementation of digitization will aim to enhance quality and efficiency, optimize cost and create process synergies within the Haitian Group. Mr Zhang Bin, Executive Director of Haitian International: “We will promote standardized production of components while meeting the needs of each market segment and individual customers, based on our product strategy “Technology to the Point. Haitian will continue to create value for its customers with better quality and more convenient services, and grow hand in hand with customers, employees, partners and investors.”

Environmental, social, governance

Haitian International has always taken its social responsibility very seriously. In the interest of the sustainable development of the company the industry and our planet Haitian will strengthen the research and implementation of clean, environmentally friendly technologies, introduce special machines for processingbiodegradable materials, and accelerate the development of the next generation of machines designed to be even more energy efficient.

This year, Haitian will publish an environmental, social and governance (ESG) report outlining the milestones of the past years and the company’s future goals.

The post HAITIAN INTERNATIONAL CONTINUES TO SET NEW RECORDS IN 2021 appeared first on Haitian Group.

]]>On September 16, 2021, the Haitian Experience Center officially opened in Ningbo, China. The The venue creates an interactive experience that spans the history of Haitian, the present and the future.

On around 500 square meters at the Haitian Group headquarters in Ningbo, China, customers, partners and other visitors are now able to experience the Haitian brand up close. The showroom covers different topics such as Haitian’s origins, the branding of the individual divisions, their business areas as well as general brand values and company insights, future developmentsand many more. The individual topics are brought to life by a combination of state of the art technology such as interactive videos, virtual and physical objects, pictures and texts. The guided tour takes about 20-30 minutes and will be offered in several languages in the future.

With the Experience Center, Haitian not only provides an insight into the current operations of the individual divisions, but above all allows its visitors an outlook on its future developments especially in the digital sector. The showroom thus symbolizes the transformation of the company from a classic machine manufacturer to an innovative digital company, which has already begun.

Haitian welcomes all of its visitors to take a tour of the showroom.

The post Haitian Experience Center officially opened appeared first on Haitian Group.

]]>Today the Haitian Group celebrated the opening of the Haitian Culture and Sports Center!

This facility for sure marks milestone within Haitian Group history. On roughly 4.6 hectares the stadium will offer the entire community a high-standard modern cultural and sports center integrating several sports facilities such as a soccer field, tennis courts, a basketball court, ping-pong halls, a gym and many more. It also offers performing and arts facilities, cultural and leisure areas and even includes a cinema!

Thanks to all our partners and workers that contributed to this great project!

The post the opening of the Haitian Culture and Sports Center! appeared first on Haitian Group.

]]>Backed by its experience to shape smart manufacturing

To better respond to the transformation and modernization needs of the manufacturing industry, on June 18, 2021, Haitian Group announced the establishment of a new company – Ningbo Haitian Smart Solutions Technology Co., Ltd. Haitian Group President Zhang Jianming, Haitian Group Vice President Zhang Jianfeng, Haitian Group Vice President Zhang Bin, Haitian Smart Solutions General Manager Zhang Jianbo and other executives attended the establishment ceremony.

As a new business under Haitian Group, Haitian Smart Solutions will focus on identifying the various needs of manufacturing enterprises for digital transformation and providing flexible, efficient and cost-effective smart manufacturing solutions for the manufacturing industry.

Three business units with holistic service

At the ceremony, Haitian Group President Zhang Jianming and Haitian Group Vice President Zhang Bin each delivered opening speeches, setting high expectations for the development of Haitian Smart Solutions. They encouraged the Haitian Smart Solutions team to always act from the perspective of customer needs to create a holistic management system for manufacturing equipment and provide better services to customers.

Then Zhang Jianbo, General Manager of Haitian Smart Solutions, introduced the main business under the philosophy of “Connectineers for intelligent factories”. Haitian Smart Solutions will feature three business divisions: Smart Factory Planning, Auxiliary Equipment, and Information Systems. The production and decision-making process of manufacturers are comprehensively covered by these three areas and will be complemented by holistic digital service approach.

The establishment of Haitian Smart Solutions, based on the long-standing manufacturing experience of Haitian Group, is a milestone for the future development of the entire Group and enables the full potential of each Haitian Group industry based on far-reaching synergies.

As a new comprehensive service platform for intelligent manufacturing, Haitian Smart Solutions will steadily expand its scientific and technological research and development, and successively develop its core technology. “Through technology and services, we will help manufacturing companies improve quality and efficiency, digitally transform enterprises, and create a new paradigm of the smart manufacturing factory.

The post Official Foundation of Ningbo Haitian Smart Solutions Technology Co., Ltd. appeared first on Haitian Group.

]]>On June 18, the “Ceremony for Completion of Haitian Die Casting Ningbo Bonded Area Base & the Signing Ceremony for Strategic Cooperation on Ultra-large Die Casting Machines” was held at Ningbo Beilun Port Comprehensive Bonded Area, on which Haitian Die Casting signed the strategic cooperative agreements on ultra-large die casting machines respectively with Ningbo Xusheng Auto Technology Co., Ltd., Chongqing Millison Technology Co., Ltd. and Anhui Huihan Precision Machinery Co., Ltd.

At the ceremony, over 300 people – cooperative partners and clients of Haitian Die Casting, as well as media friends – were present, including Yan Rongjie, Secretary of the Party Working Committee of the Bonded Zone and Director of the Administrative Committee, Zhang Jianming, President of Haitian Group, Yue Xiaodong, General Manager of Haitian Die Casting, and Yu Yajun, President of Millison Technology.

01 Found a new base and create a new start

It is learned that Haitian Die Casting Ningbo Bonded Area Base is built on the floor area of 139mu with total investment of US$ 160 million and covered area about 75,000m2 and is a base integrating the customization, processing, production, after sales, die trial and personnel training with regard to complete set of large die casting machines and providing holistic solutions for die castings.

Imported large floor-type boring and milling machine of SKODA

The base applied with advanced production equipment and technologies is designed scientifically in such aspects as production capacity, product, logistics, intelligent manufacturing, application center and environmental protection and makes sufficient use of digitalized platforms and flow manufacturing mode to gradually enable the annual production capacity of 4,000 die casting machines. The maximum tonnage of machines manufactured in the base could be 6600T and 8800T, which could meet the requirement for ultra-large die casting machines used in industries of lightweight of automotive, new energy vehicles, and 5G communications.

02 Leaders’ address and grand opening of the ceremony

Speech from Yue Xiaodong, General Manager of Haitian Die Casting

In the speech he indicated that: Haitian Die Casting Ningbo Bonded Area Base has a far-reaching significance on expansion of production capacity, market development and comprehensive transformation and upgrading. Haitian Die Casting will seize the development opportunity and build our product into the most competitive and cost-effective die casting equipment worldwide, thus making positive contributions to the flourishing die casting industry of our country.

Speech from Zhang Jianming, President of Haitian Group

On the site, he showed gratitude for friends and partners from all walks of life in support of the base construction and delivered a speech: Haitian Die Casting will take this opportunity and forge ahead with determination to realize intensive operation of metal forming equipment. Make sustained innovations in technologies, design and manufacture the die casting machine boasting the maximum tonnage globally, provide the highly-efficient, durable and intelligent ultra-large high-end die casting equipment and do all we can to be the bellwether in die casting industry.

Speech from Yu Yajun, President of Chongqing Millison Technology Co., Ltd.

In the speech, he sent warm congratulations: Haitian Die Casting is an outstanding national enterprise, a trustworthy partner, and a good brother! The launch of this new base in Ningbo Bonded Area marks the transformation of Haitian Die Casting, is a milestone in boosting intelligent manufacture, and sets a new pole for and a new force in Chinese equipment industry! I wish Haitian Die Casting will continue to provide customers with high-quality products and services and strive for the common goal of thriving development of Chinese intelligent manufacture worldwide!

Speech from Yan Rongjie, Director of the Administrative Committee of Ningbo Bonded Area and Secretary of the Party Working Committee

In the speech, he stressed: Since the start of construction of Haitian Die Casting project in 2019, Haitian people have overcome the influence of the epidemic, raced against time, made breakthroughs in die casting equipment simultaneously with the construction and obtained significant results. They established “5G+ Haitian Die Casting Global Application Center”, accomplished the research of 8800T die casting machine and became the “heavy machine of the state” of metal die casting equipment, showing the mien of Haitian people. And I would like to give you a thumb-up.

03 Multiple powers cooperate and sign agreements

Site of the signing ceremony

Haitian Die Casting grows up to be a power depending on the great support of customers. In rapturous applauses, Yue Xiaodong, General Manager of Ningbo Die Casting, Yu Yajun, President of Chongqing Millison Technology Co., Ltd., Lin Guofeng, President of Ningbo Xusheng Auto Technology Co., Ltd., and Zhe Huiming, President of Anhui Huihan Precision Machinery Co., Ltd. appeared on the stage to sign the agreement on Strategic Cooperation on Ultra-large Die Casting Machines, joining hands to open a new chapter of development!

04 Witnessing the moment of launch and lifting up the first-rate industry

Launch ceremony of the base

After fulfillment of the agreement signing, leaders at the ceremony moved their steps on the stage and scattered gold dust on the gold-plated launchpad to announce the official completion and launch of Haitian Die Casting Ningbo Bonded Area Base, including Mr. Yan Rongjie, Mr. Ye Wandang, Mr. Yu Bin, Mr. Zhang Jianming, Mr. Yu Yajun, Mr. Zhang Jianfeng, Mr. Zhag Bin and Mr. Yue Xiaodong.

Ceremony for unveiling the stone lions of the office building

Afterwards, in front of the office building of Haitian Die Casting, Zhang Jianming and Yue Xiaodong, respectively the President of Haitian Group and General Manager of Haitian Die Casting, unveiled the stone lines, concluded the satisfactory launch ceremony for Haitian Die Casting Ningbo Bonded Area Base.

The launch of Haitian Die Casting Ningbo Bonded Area Base marks the continuous speed-up and improvement of Haitian Die Casting’s strategy layout, providing powerful supply ability for production and research strength for its ever increasing market demands, assisting it to provide service nationwide and go out internationally with strong industrial base and powerful production chain.

Prospect

In the future, Haitian Die Casting will rely on the new base and take it as a carrier, comprehensively reinforce the production capacity of various machinery types and gradually improve the research and manufacture of high-end product. Meanwhile, it will aim at the cutting-edge industrial technologies and key areas, devotes to breaking through the technological bottleneck and continuously promote the successful scientific and technological innovation results in die casting industry, so as to create the first-rate world-leading domestic die casting machinery manufacturing base.

The post Haitian Die Casting Bonded Area Base Launched Officially appeared first on Haitian Group.

]]>2020 track record: More than RMB 11.8 billion in sales and over 43,000 machines sold

Haitian International successfully defied the Corona pandemic +++ Sales record with more than 43,000 machines +++ Annual sales up 20.3 % +++ 28.6 % sales increase for best-selling Mars Series +++ Special focus on digitalization.

?March 22, 2021, Hong Kong. Haitian International Holdings Limited (stock code: 1882), one of the world’s largest manufacturers of plastic injection molding machines, announces its annual results for 2020 (January 1 to December 31, 2020).

Global economy and business performance

In 2020, the Covid 19 virus outbreak and its rapid spread into a pandemic severely shook the entire global economy. Nearly all countries and all major economies in the world are still reeling from the effects today. China’s economy benefited from strict preventive and control measures taken by the government and was soon able to return to positive growth and normal economic operation. Thanks to this rapid recovery in the domestic economic situation, the entire Group experienced strong, growing demand.

As a result, Haitian International posted a new sales record for the completed 2020 fiscal year, with well over 43,000 machines sold. This represents total sales of RMB 11,800.1 million and a year-on-year increase in sales of 20.3 percent.

Export increase due to global network

Although sales in some overseas markets were severely affected by the pandemic, the holding company recorded an increase in export sales thanks to the continuous expansion of its global network. They increased by 2.1% to RMB 3,518.5 million despite the pandemic.

Due to the strong demand for mass medical products and packaging in the first half of the year, there was a new sales record of the Haitian Mars Series with more than 37,000 machines sold. As a result, the 2020 annual sales of the best-selling Series increased by 28.6% year-on-year to RMB 8,214.5 million. The household goods and automotive markets also saw growth in 2020, despite Corona. This mainly benefited the electric Zhafir Series as well as the Haitian Jupiter Series with two-plate technology. Here, sales increased by 6.8% to RMB 1,439.9 million and by 3.2% to RMB 1,303.0 million, respectively.

Outlook and future strategy

Haitian International formulated a general overview of its five-year plan strategy at the beginning of 2021. Key objectives include strengthening its global market presence and consistently expanding its market share. Mr. Zhang Bin, Executive Director of Haitian International, said, “With industry-specific solutions, we will increase competitiveness in the high-end market, among others, and advance digital manufacturing solutions.” Of particular importance in this context is the digitalization of in-house manufacturing, especially in terms of R&D, intelligent production processes, digital system integration and process control.

Furthermore, the focus is on the standardization of building components to further increase efficiency, especially in the optimization of technologies as well as smart manufacturing. “With the establishment of a young and innovative team, we will focus more on manufacturing processes and improve production capabilities in terms of flexibility and intelligence. The entire Group will continue to work hard to grow and develop successfully together with customers, employees and business partners in the future.”

The post 2020 track record appeared first on Haitian Group.

]]>Haitian celebrates the official groundbreaking in Shunde County, near Foshan City in Guangdong Province, for the construction of a Smart Factory for advanced component and machinery manufacturing.

?Shunde, March 18, 2021 – Eight months after signing the investment cooperation agreement (July 9, 2020), the official groundbreaking ceremony of the joint initiative between Haitian and the governments of Guangdong and Foshan has now commenced.

The participants of the groundbreaking ceremony were high-ranking, first of all Mr. He Rong, Advisor of the Ministry of Industry and Information Technology of Guangdong Province and Mr. Zhu Wei, Mayor of the 7-million-metropolis Foshan as well as well-known representatives of the local and regional party committees. For Haitian, Chairman Zhang Jingzhang of Haitian Group, President Zhang Jianming and President Zhang Jianfeng of Haitian Plastics Machinery and Vice President Zhang Bin of Haitian Group, as well as well-known representatives of the plastics industry were present. Together, they witnessed the historic moment that will take future cooperation between Haitian and the emerging region to a new level.

Modernization and transformation

For Haitian, the ceremony marks the beginning of a new chapter in the smart manufacturing industry; for Shunde District, it is seen as a pioneering step towards the realization of high-end industrial projects as part of the region’s urban and economic development. The ceremony symbolizes mutual trust and benefit across times and regions to form a win-win cooperation. The local environment will be fully involved in the company’s upstream and downstream value chain, helping to root Haitian in southern China. Going forward, Haitian will work with the local manufacturing industry and regional governments to share urban development opportunities, promote the modernization and transformation of the manufacturing industry, and create new opportunities in the field of “digital intelligence.”

Total investment of nearly RMB 10 billion

With the foundation stone in South China, more momentum will come to Haitians future development, and will open up new fields in the area of high-end intelligent machining. The new high-end industrial facility is not only an important strategic step in Haitian’s 14th Five-Year Plan but will also act as the second pillar of the company’s “Double Center” strategy. A second, autonomous headquarters within China that will completely supply the South China market.

With a total investment for the entire industrial park of nearly 10 billion RMB, the first phase of construction will mainly be for the production and manufacturing of intelligent injection molding machines on an area of around 300,000 square meters. Later, they will be complemented by CNC machine tools, robotics and automation and intelligent manufacturing systems to form an ecological and intelligent R&D and manufacturing park of Haitian. Mr. Zhang Jianming, President of Haitian Group, said in his speech, “With intelligent technologies and digital platforms as the basis, and through mindful, proactive management of the flexible production line, we will build this plant into a model of intelligent manufacturing.”

The post Haitian Group starts construction of Smart Factory in South China appeared first on Haitian Group.

]]>