HAITIAN’S MULTI-COMPONENT LAMP MOLDING SOLUTION HELPS THE DEVELOPMENT OF NEW ENERGY VEHICLES

2022-07-22

Accelerated growth of new energy vehicles

In recent years, as the market demand for new energy vehicles has exploded and sales have continued to reach record highs. In 2022, the new energy vehicle industry is still developing rapidly. In the first quarter, the total sales volume reached 1,004.2 million RMB, and the penetration rate increased to 21.1%, showing an accelerating upward trend.

According to the statistics of the Ministry of Industry and Information Technology of the People’s Republic of China, 10.33 million new energy vehicles have been promoted in China, making China an important force leading the development of the global new energy vehicle industry. The automotive industry is ecologically booming, and the competitive market among major new energy vehicle brands will expand.

Haitian helps new energy vehicle brands to grow

New industries are changing day by day and the formation of new markets is accelerating. Under the wave of new energy vehicles, also the injection molding industry has seen a new development direction. Plastic injection-molded products are widely used in the field of new energy vehicle manufacturing because of their light weight, good electrical insulation, corrosion resistance and other characteristics.

While demand is growing, the market puts forward higher requirements for the quality of parts. Facing the increasingly fierce competition in the market, how can injection molding machines help car companies to further strengthen their advantages in the manufacturing end?

As the industry leader and technology pioneer of domestic plastic machines, Haitian has achieved great results in the process of cultivating the field of new energy vehicles and obtained a number of national invention patents and utility model patents, filling the gap in the industry and exploring more ways for new energy vehicle enterprises to improve quality and efficiency.

In the multi-component field, Haitian continues to increase technology research and development in response to the lightweight development trend of new energy vehicles and takes the lead in launching the industry-leading two-color lamp bi-injection molding solution to create a more competitive lighting solution with leading quality, and help new energy vehicle brands to develop and grow.

Haitian multi-component vehicle lamp bi-injection molding solution

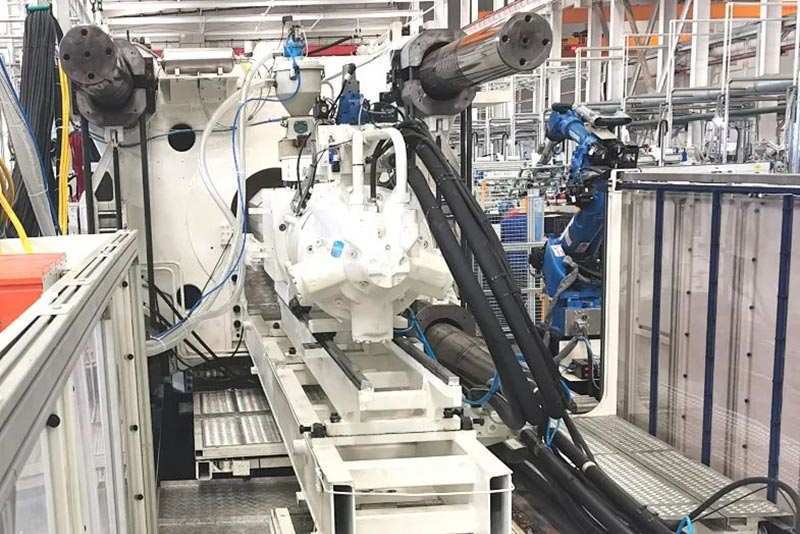

Based on the popular?JUIII?platform of Haitian and relying on the profound accumulation of multi-component molding technology, the?bi-injection molding solution?provided for the new energy vehicle industry is more flexible and efficient. It can easily handle the injection molding of high-quality two-color lamps, effectively improve the quality and appearance conditions of lamps, realize cost reduction and efficiency increase and bring significant cost and technical advantages to new energy vehicle manufacturers.

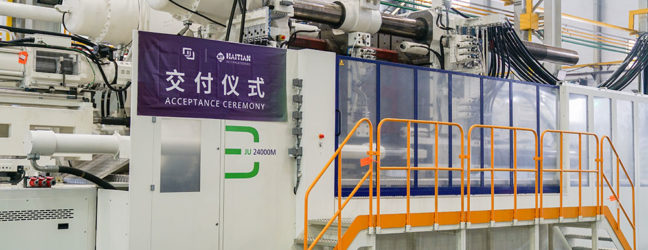

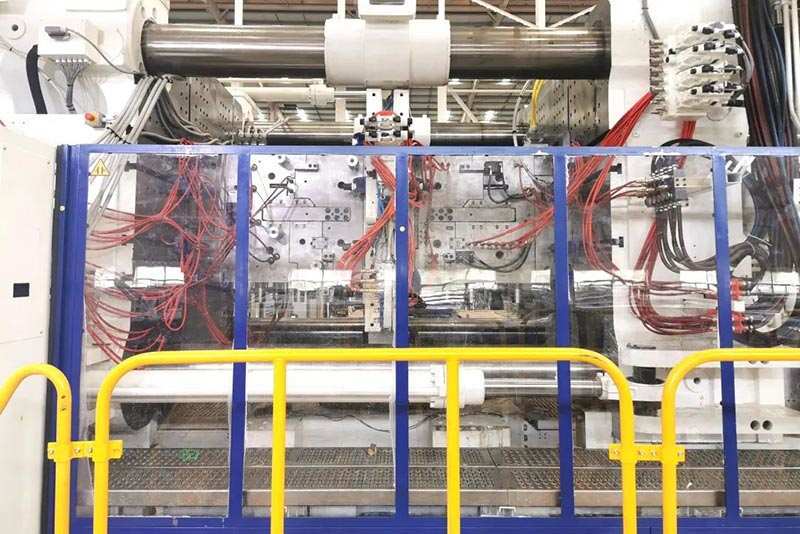

Haitian JU24000M/6730-A6730, with?a mold locking force of 2,400T, is the first 2,400T bi-injection model in China. The whole machine is designed according to the horizontal rotary table technology. The main/auxiliary injection device is installed on the side of the movable and fixed mold plates respectively, where the movable horizontal rotary table or the rotating mold is supported by its own base frame, making the mold more compact. It can be used as a multi-purpose machine or as two single-color injection molding machines to meet the customer’s demand of producing large two-color products.

JU24000M/6730-A6730

Equipment features:

- The advanced horizontal rotation technology can achieve double capacity in a smaller mold frame and significantly shorten production cycle time and reduce electricity and water costs.

- Larger mold holding space and stronger load-bearing capacity of rotary table facilitate stable production of large molds.

- Reasonable mold cavity distribution is beneficial to mold structure design, and is suitable for the production of each large-scale multi-component parts.

- Flexible design realizes more freedom and functional integration in the field of new energy vehicle manufacturing.

Applications

- Model: JU24000M/6730-A6730

- Product: Headlight mask (SA3F)

- Single weight: 690 g

- Number of cavities: 2

- Raw material: PC

- Industry: Automotive industry – lamp components

- Features: Two-color bi-injection process

Molding the future together

Recently, a number of Haitian multi-component bi-injection molding machines have been successively installed in domestic new energy vehicle manufacturing plants and put into production. In the future, Haitian will continue to cooperate with major new energy vehicle manufacturers to continuously meet the needs of the industry, jointly build a more sustainable industrial ecology, and drive the new energy vehicle industry onto the fast lane of green development.